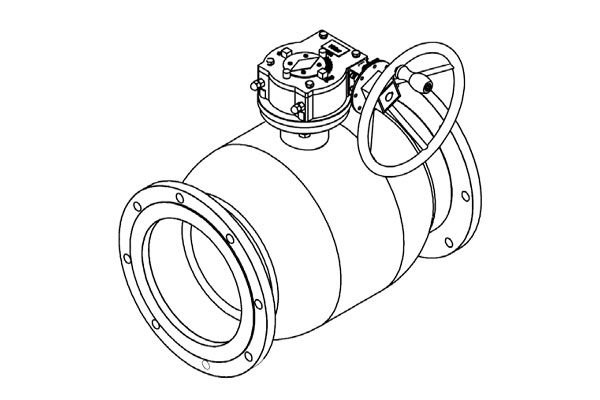

400PSI/Class250

Reduced Bore, Lever Handle, Floating Ball

Design to EN488

Pressure to EN12266.1

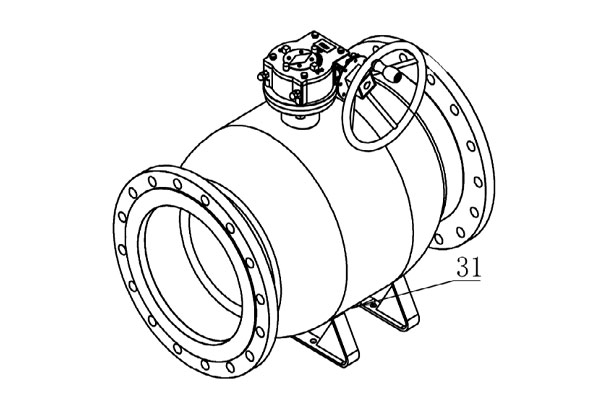

400PSI/Class250

Reduced Bore, Lever Handle, Floating Ball

Design to EN488

Pressure to EN12266.1

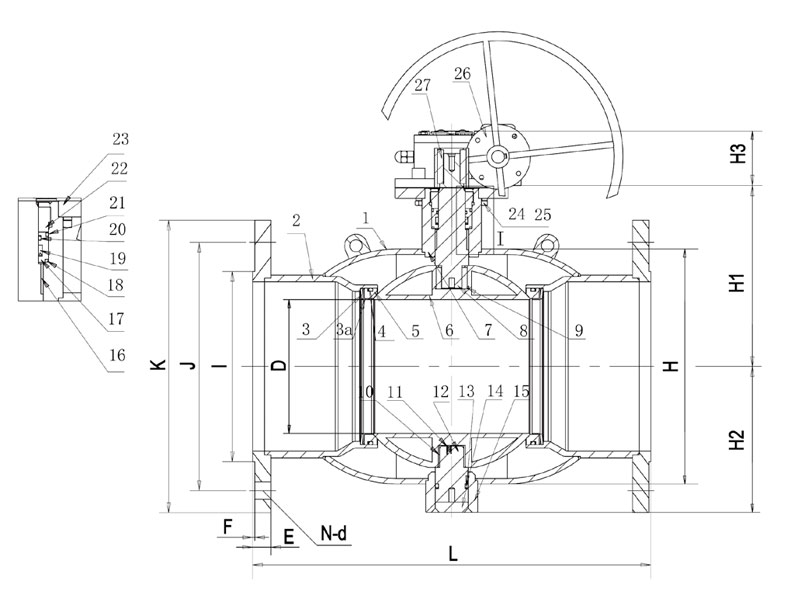

| 1 | Body | A106-B, EN10217-2 |

| 2 | Welded Pipe | A106-B, EN10217-2 |

| 3 | Spring | AISI 304, EN10088-3 |

| 3a | Fireproof Gasket | AISI 304 |

| 4 | O-Ring | Viton |

| 5 | Seat Ring | PTFE 25%C |

| 6 | Ball | AISI 304, EN10088-3 |

| 7 | Stem Guide | A106-B, EN10217-2 |

| 8 | Stem | ASTM A420, EN10088-3 |

| 9 | Lock Key | AISI 1045 |

| 10 | Bearing | AISI 304 PTFE |

| 11 | Anti-Static Device | AISI 304 |

| 12 | Fixing Bushing | ASTM A105 |

| 13 | O-Ring | Viton |

| 14 | Closure | ASTM A53-F |

| 15 | Bottom Bushing | A106-B, EN10217-2 |

| 16 | Bearing | AISI 304 PTFE |

| 17 | Gland Cover | A106-B, EN10217-2 |

| 18 | O-Ring | AViton |

| 22 | Gland | A106-B, EN10217-2 |

| 23 | ISO Flange | ASTM A105 |

| 24 | Bolt | ASTM A193-B7 |

| 25 | Spring Washer | ASTM 1566 |

| 26 | Gearbox | ASTM A536 |

| 27 | Lock Key | AISI 1045 |

| 28 | Lifting Lug | ASTM A53-F |

Operating temperature range: -30℃ ~ +200℃ .

For other materials and special requirements, please consult the factory or the local offices.

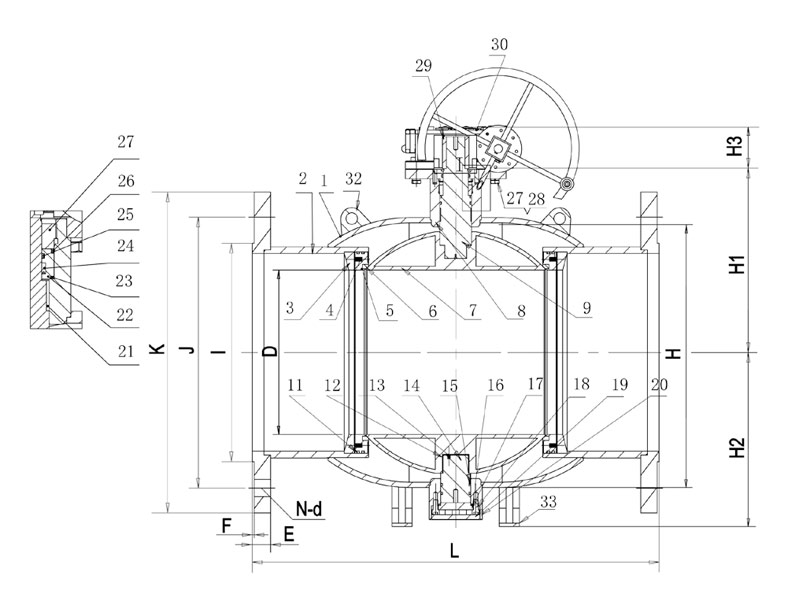

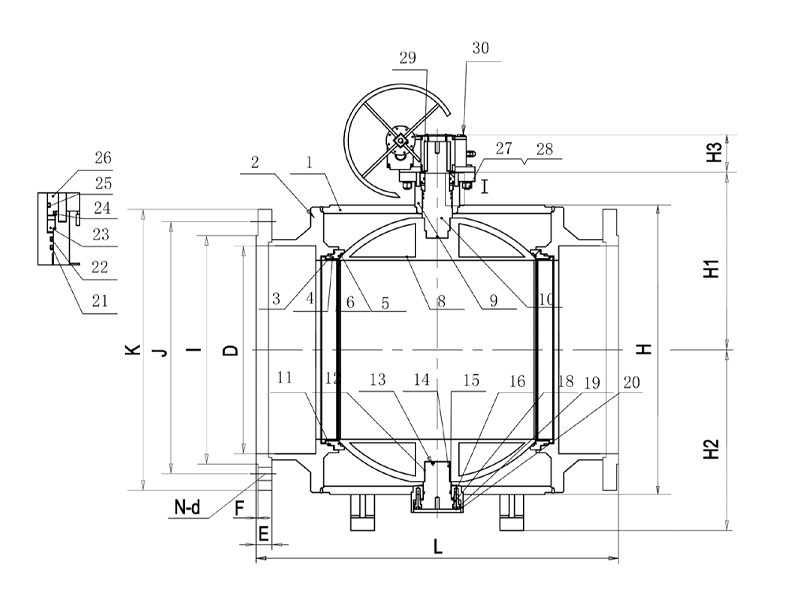

| 1 | Body | A106-B, EN10217-2 |

| 2 | Welded Pipe | A106-B, EN10217-2 |

| 3 | Baffle | ASTM A105 |

| 4 | Spring | AISI 304, EN10088-3 |

| 5 | Seat Ring | PTFE 25%C |

| 6 | Pressure Ring | ASTM A105 |

| 7 | Ball | AISI 304, EN10088-3 |

| 8 | Stem Guide | A106-B, EN10217-2 |

| 9 | Stem | ASTM A420, EN10088-3 |

| 11 | O-Ring | Viton |

| 12 | Bearing | AISI 304 PTFE |

| 13 | Anti-Static Device | AISI 304 |

| 14 | Fixing Bushing | ASTM A105 |

| 15 | O-Ring | Viton |

| 17 | End Cap | ASTM A53-F |

| 18 | Screw | ASTM A193-B7 |

| 19 | Closure | ASTM A53-F |

| 20 | Bottom Bushing | AISI 1020 |

| 21 | O-Ring | Viton |

| 23 | Gland | AISI 1020 |

| 24 | O-Ring | Viton |

| 26 | ISO Flange | ASTM A105 |

| 27 | Spring Washer | ASTM 1566 |

| 28 | Bolt | ASTM A193-B7 |

| 29 | Lock Key | AISI 1045 |

| 30 | Gearbox | ASTM A536 |

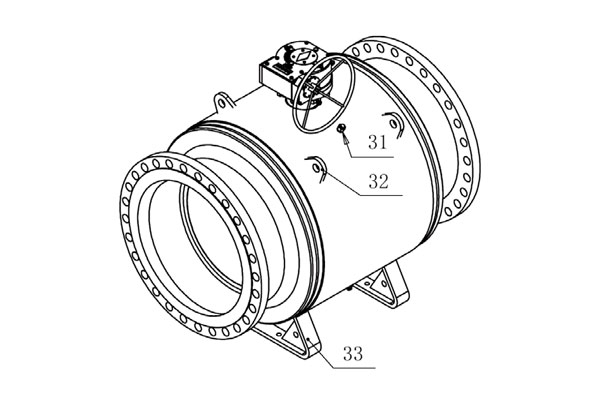

| 31 | Exhaust Valve | AISI 1025 |

| 32 | Lifting Lug | ASTM A53-F |

| 33 | Seat | ASTM A53-F |

Operating temperature range: -30℃ ~ +200℃ .

For other materials and special requirements, please consult the factory or the local offices.

| 1 | Body | A106-B, EN10217-2 |

| 2 | Welded Pipe | A106-B, EN10217-2 |

| 3 | Baffle | ASTM A105 |

| 4 | Spring | AISI 304, EN10088-3 |

| 5 | Seat Ring | PTFE 25%C |

| 6 | Pressure Ring | ASTM A105 |

| 7 | Ball | AISI 304, EN10088-3 |

| 8 | Stem Guide | A106-B, EN10217-2 |

| 9 | Stem | ASTM A420, EN10088-3 |

| 11 | O-Ring | Viton |

| 12 | Bearing | AISI 304 PTFE |

| 13 | Anti-Static Device | AISI 304 |

| 14 | Fixing Bushing | ASTM A105 |

| 15 | O-Ring | Viton |

| 18 | Screw | ASTM A193-B7 |

| 19 | Closure | ASTM A53-F |

| 20 | Bottom Bushing | AISI 1020 |

| 21 | O-Ring | Viton |

| 23 | Gland | AISI 1020 |

| 24 | O-Ring | Viton |

| 26 | ISO Flange | ASTM A105 |

| 27 | Spring Washer | ASTM 1566 |

| 28 | Bolt | ASTM A193-B7 |

| 29 | Lock Key | AISI 1045 |

| 30 | Gearbox | ASTM A536 |

| 31 | Exhaust Valve | AISI 1025 |

| 32 | Lifting Lug | ASTM A53-F |

| 33 | Seat | ASTM A53-F |

Operating temperature range: -30℃ ~ +200℃ .

For other materials and special requirements, please consult the factory or the local offices.

| Dimensions/Weights | |||||||||||||||

| In | D | H | L | H1 | H2 | H3 | I | J | K | E | F | N-d | Kvs | Lbs | Kg |

| 6 | 125 | 219 | 403 | 182 | 150 | 81 | 218 | 250 | 300 | 30 | 3 | 8-Φ25 | 1120 | 135 | 61 |

| 8 | 150 | 273 | 502 | 226 | 174 | 81 | 278 | 310 | 360 | 34 | 3 | 12-Φ25 | 1620 | 203 | 92 |

| 10 | 200 | 351 | 568 | 267 | 230 | 81 | 332 | 370 | 425 | 36 | 3 | 12-Φ30 | 3300 | 337 | 153 |

| 12 | 250 | 426 | 648 | 307 | 277 | 90 | 390 | 430 | 485 | 40 | 4 | 16-Φ30 | 4600 | 584 | 265 |

| Dimensions/Weights | |||||||||||||||

| In | D | H | L | H1 | H2 | H3 | I | J | K | E | F | N-d | Kvs | Lbs | Kg |

| 14 | 300 | 508 | 762 | 347 | 335 | 96 | 448 | 490 | 550 | 44 | 4 | 16-Φ34 | 8300 | 845 | 383 |

| 16 | 335 | 560 | 838 | 384 | 376 | 107 | 505 | 550 | 610 | 48 | 4 | 16-Φ34 | 12500 | 1195 | 542 |

| 18 | 385 | 640 | 914 | 425 | 425 | 107 | 555 | 600 | 660 | 50 | 4 | 20-Φ34 | 15300 | 1828 | 829 |

| 20 | 438 | 735 | 991 | 480 | 497 | 107 | 610 | 660 | 730 | 52 | 4 | 20-Φ41 | 18000 | 1956 | 887 |

| Dimensions/Weights | |||||||||||||||

| In | D | H | L | H1 | H2 | H3 | I | J | K | E | F | N-d | Kvs | Lbs | Kg |

| 24 | 590 | 805 | 1143 | 546 | 540 | 125 | 718 | 770 | 840 | 56 | 5 | 20-Φ41 | 29000 | 2838 | 1287 |

| 28 | 685 | 965 | 1346 | 625 | 635 | 146 | 815 | 875 | 955 | 60 | 5 | 24-Φ48 | 35000 | 5089 | 2308 |

| 32 | 780 | 1120 | 1524 | 702 | 710 | 157 | 930 | 990 | 1070 | 64 | 5 | 24-Φ48 | 52000 | 7246 | 3286 |

| 36 | 874 | 1280 | 1727 | 790 | 810 | 157 | 1025 | 1090 | 1180 | 66 | 5 | 28-Φ54 | 58000 | 10330 | 4685 |

| 40 | 976 | 1410 | 1900 | 865 | 885 | 187 | 1140 | 1210 | 1305 | 68 | 5 | 28-Φ58 | 75000 | 13662 | 6196 |

| 48 | 1166 | 1570 | 2180 | 965 | 980 | 187 | 1350 | 1420 | 1525 | 72 | 5 | 32-Φ58 | 108000 | 18908 | 8575 |

Please consult the engineers for full-bore dimensions.

Copyright © TALOAR All Rights Reserved