As the name implies, an air vent is a kind of valve that releases excess air from piping or equipment. In various industrial systems, due to liquid flow, temperature changes and other factors, the phenomenon of gas aggregation often occurs. If these gases are not discharged in a timely manner, there is a risk of equipment failure, pressure fluctuations and even system explosion. The air vent ensures the smooth flow of fluid in the pipeline through automatic exhaust or manual adjustment. This demonstrates the importance of air vents. This article will discuss the structure and working principle, types and applications of air vents.

Structure and Working Principle

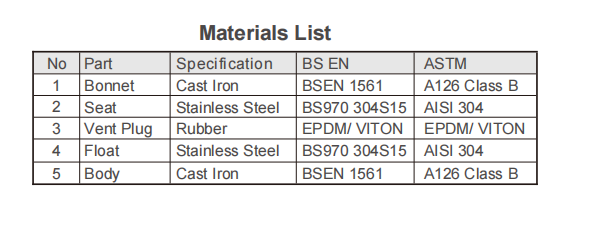

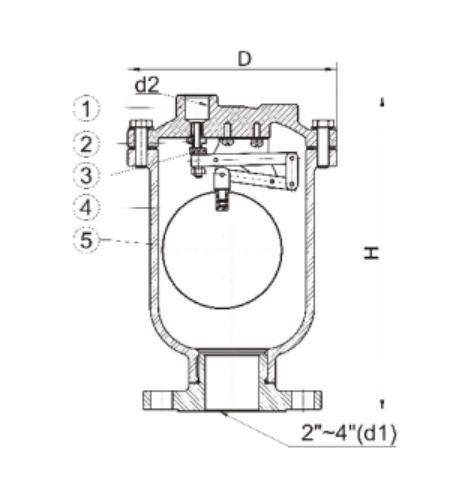

The air vent comprises a body, bonnet, float, lever, bonnet seal and vent cap. (Here takes Taloar VT-690 as an example.)

The internal structure of the Taloar air vents comprise a lever and a float connected by a movable linkage. This design eliminates the risk of rust and corrosion that can occur with other, similar products when used over an extended period.

The top vent is an independent sealing structure that ensures only exhaust air is discharged.

Types of Air Vents

There are numerous classifications of air vents. But in this article, let’s focus on the classification based on the material used.

Brass air vent VT50

Iron air vent VT-690

Iron air vent

½ ″ - 1 ″

PN16/235PSI

Large Venting Volume, Stainless Steel Float

Dimension to EN1092-2, ANSI B16.1 Class125

Threaded Ends Comply to BS21 or ANSI 2.1

Iron air vent VT660

2 ″ - 4 ″

PN16/235PSI

Large displacement, stainless steel float

Threaded connection conforms to BS21 taper screw (ISO7) and NPT screw

Flange size meets EN1092-2, ANSI B16.1 Class 125

Stainless steel air vent VT-360

½ ″ - 1 ″

PN16/235PSI

Large Venting Volume, Stainless Steel Float

Threaded Ends Comply to BS21 or ANSI 2.1

Application

As a professional valve manufacturer, Taloar is dedicated to providing each customer with the highest quality air vents. Taloar’s PP polypropylene floats are temperature resistant up to 110 ℃ and will not deform when immersed in hot water for an extended period. Our stainless steel floats are temperature resistant up to 220 ℃ and have a longer service life without deformation. The air vent body material can be provided in alloy copper, cast iron and stainless steel, and the sealing material can be selected from NBR rubber and EPDM or VITON exhaust plugs. When you require customized air vents, we would be delighted to offer service.

If you need to keep up with innovations and technological advancements in air vents, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved