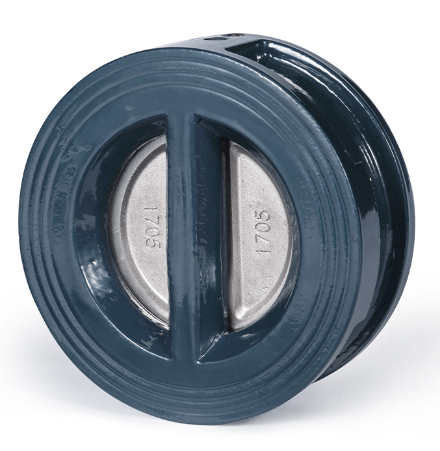

The dual plate check valve is a one-way valve designed to prevent the backflow of fluid media. It is composed of two symmetrical plates and is typically installed in pipelines. The valve is controlled by opening and closing the plate, allowing for the regulation of the fluid flow in a one-way direction. It is a highly versatile solution that is widely used in industrial and civil fluid control systems.

Working Principle of the Dual Plate Check Valve

Forward flow: When the medium in the pipeline flows in a positive direction, the medium pressure causes the valve plate to rotate around the central axis, opening the valve and allowing the fluid to pass.

Reverse flow: In the event of a drop in media pressure or a reverse flow, the spring force and the reverse pressure of the media act in conjunction to rapidly close the valve plate, effectively halting the backflow of media.

Closing process: The innovative overlapping design and cushioning effect of the valve plate during closing effectively reduces the water hammer phenomenon and provides comprehensive protection for the piping system.

Characteristic of the Dual Plate Check Valve

Dual plate structure

The valve body is designed with dual plates, which facilitate a more rapid opening and closing process, while also reducing the backflow shock. Furthermore, the dual plate design contributes to a reduction in overall weight and operating torque.

Low fluid resistance

The valve plate’s large opening angle ensures low fluid resistance, allowing the fluid to pass through with minimal energy loss.

Easy installation

It typically uses a wafer connection, requires minimal space, and can be installed in either a horizontal or vertical orientation.

Good corrosion resistance

According to the specific working conditions, the customer can select from a range of materials, including stainless steel, cast steel and other materials. With different sealing materials (such as NBR, VITON, etc.), the product can be adapted to a variety of media and environments.

Economical

Compare with traditional check valves, dual plate check valves are a lighter and less costly option.

Application

Water treatment system

Dual plate check valves are often used in systems such as city water supply, sewage treatment, desalination and more to prevent backflow of water, which can otherwise damage the equipment.

Industrial piping

In the context of industrial pipelines, such as those used in the petroleum, chemical, metallurgy and other industries, dual plate check valves are used in pipeline systems for the conveyance of liquids, gases and steam to prevent the medium from flowing back.

Pump station system

The installation of dual plate check valves at the pump outlet serves to prevent shock or damage to both the pump and the system as a whole. This is achieved by preventing backflow, which can occur when the pump suddenly stops running.

HVAC systems

The installation of check valves in cooling water or coolant circulation piping prevents backflow from adversely affecting heat exchange and equipment operation throughout the system.

Power stations and energy sector

Dual plate check valves are used in steam or cooling water piping in thermal, hydroelectric or nuclear power plants to prevent backflow from the system.

Installation

Installation position and direction

It is essential to ensure that the flow direction marking on the valve is aligned with the actual medium flow direction in the pipeline.

The installation position should be on a horizontal pipeline or a pipeline with a slight inclination. When installed vertically, the medium must flow from the bottom to the top.

Pipe preparation

Clean the pipeline thoroughly to remove any welding slag, iron filings, rust or other debris that may enter the valve and cause damage.

Ensure that the pipe flange end faces are flat and smooth in order to guarantee optimal sealing performance.

Installation clearance

It is important to use the correct gaskets on both sides of the valve flange during installation. The flange bolts should be tightened evenly to prevent uneven force on the valve body.

Avoid vibration

It is recommended that the installation position be as far away as possible from equipment prone to mechanical vibration. This will help to avoid any potential damage or malfunction of the valve over time.

Flow rate requirements

It is important to control the flow rate according to the design parameters of the valve model in order to avoid any adverse effects that may be caused by a high flow rate on the inner parts of the valve.

Maintenance

Periodic inspection

Please verify that the valve is sealing properly and that there is no media leakage.

Please verify that the dual plate opening and closing mechanism is flexible and that there are no jams or unusual noises.

Cleaning and maintenance

It is essential to regularly remove any dirt or scale that may have accumulated inside the valve, particularly in situations where particles or scale-prone media are being used.

It is important to avoid any prolonged blockage of the valve plate caused by foreign matter.

Replacement of seals

If the seals are worn or deteriorated, the appropriate parts should be replaced promptly to maintain the sealing performance of the valve.

Lubrication maintenance

It is important to ensure that an appropriate amount of lubricant is added to the valve hinge parts or movable joints in order to guarantee smooth movement.

Check the spring

It is recommended that the elasticity of the valve reset spring be checked on a regular basis and, should it be found to be failing or fatigued, it should be replaced.

Storage and standby

Dual plate check valves that have not been used for an extended period should be stored in a dry and ventilated location. Additionally, it is advisable to conduct regular inspections of the anti-corrosion treatment to ensure its integrity.

Taloar provides a comprehensive range of dual plate check valves, offering a variety of connections including flanged, wafer and lug type. In addition to dual plate check valves, Taloar also offers a range of other types of check valves, including silent check valves , ball non-return check valves , swing check valves and so on. If you have any special customized requirements, please do not hesitate to contact us.

If you need to keep up with innovations and technological advancements in dual plate check valve, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved