In industrial systems, pressure fluctuations caused by a sudden stop or change of direction of a fluid in a pipeline (e.g. rapid closing of a valve) must be taken into account. This phenomenon may result in piping vibration, noise, or even damage to equipment or piping, which can cause significant issues for the user. A pulsation damper , also known as a water hammer eliminator or buffer, is installed in the piping system near the source of water hammer. It is specifically designed to absorb water hammer and protect the piping system from water hammer pressure and damage to safety and security devices.

Working principle of the pulsation damper

(Take Taloar’s pulsation damper as an example.)

The pulsation damper is a special pressure storage device used for pressurized liquid. It is well known that liquid cannot be compressed. However we can solve this problem by compressing the gas.

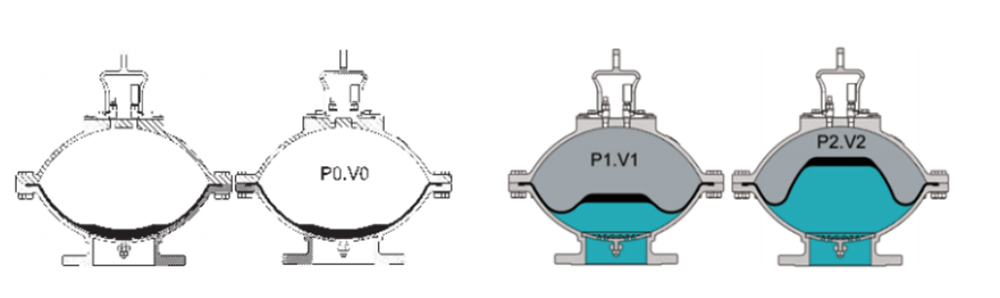

Pulsation damper has a detachable air bag with joints installed in its pressure shell.

Inert gas (nitrogen) with pressure P0 is filled into the air bag through the inlet valve until the air bag expands and fills the entire internal space of the pulsation damper with volume V0. When the circulating pressure P1 is greater than the preset pressure P0 of the gas, the hydraulic valve at the bottom will open, and the volume of the air bag will be compressed to V1 because of the effect of external circulating pressure.

If the liquid pressure increases to P2, the gas volume will decrease to V2, and pressure will increase to balance liquid pressure. That is, the air chamber inside the pulsation damper is compressed, with the volume change △V=V1-V2. That way, the energy stored in the pulsation damper can be used.

Application

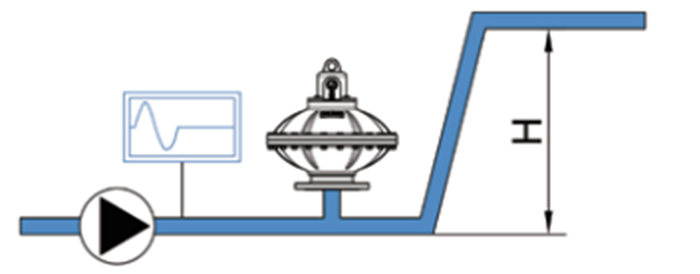

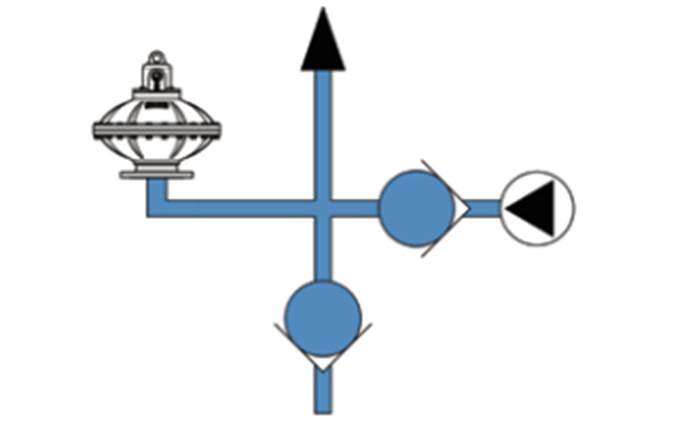

As a backpressure impact damper

If there is a sudden power off for the pump while transporting the

liquid to a high spot, the liquid in the pipeline will return and accelerate in the pipeline. Water hammer

with great destructive power will be formed at the check valve that is installed at the outlet of the pump.

If the pipeline is long, the water hammer may cause the pipeline to bust. The longer the pipeline, the

longer the fluid accelerate, the bigger the impact.

Taloar pulsation damper can effectively absorb such water hammer. Besides, Taloar pulsation damper is designed with a unique check valve structure with “fast-in and slow-out” feature, can effectively absorb water hammer instantly. It takes relatively long time to release excess pressure, ensuring stable pressure in the pipeline system.

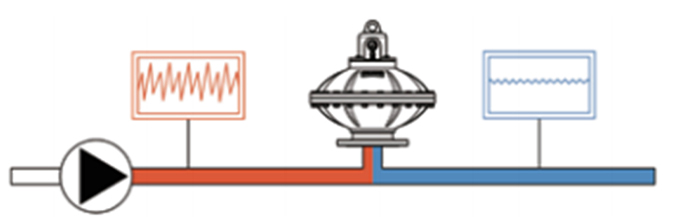

As a supply-end shock absorber

It is important to note that in the case of circulating pumps, water

hammer and hydraulic shocks are an inherent consequence of the piston’s cyclic movement. During the

discharge stroke of the pump, any excess fluid enters the water hammer eliminator, where it absorbs the

excess pressure. As the piston returns, the liquid absorbed in the water hammer eliminator re-enters the

system, replenishing the pressure drop caused by the pump piston’s return and thereby stabilizing the system

pressure.

As a suction-end shock absorber

If there is no sufficient water supply, the pump efficiency will

highly affected. Pitting is related to the fluid velocity, acceleration, and friction. If the supply at pump

suction is insufficient, vacuum will form at the supply under the suction of the pump, resulting in

“pitting”.

Install Taloar pulsation damper at the pump suction. This will act a buffer pool: If the

suction of the pump is insufficient, the liquid stored in the pulsation damper will be supplied to the

system to ensure the pump suction is sufficient. If the system supply is too large, excess liquid will enter

the pulsation damper to ensure pump suction is stable, thus greatly improving the service life of the pump.

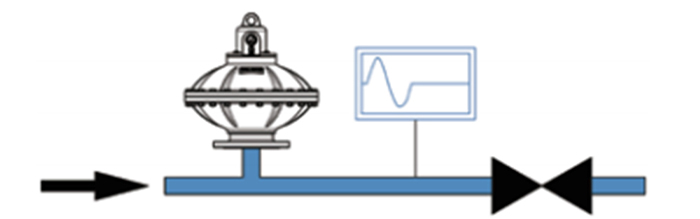

As a hydraulic impact damper

All liquid flow has kinetic energy. When the fluid suddenly stopped, its

kinetic energy will convert into pressure and this very dangerous. Such “water hammer phenomenon” usually

occurs in pipeline systems with quick-closing valves. The destructive power generated by “water hammer

phenomenon” is strong enough to damage devices like pipelines, valves, and pumps.

There are many

reasons for “water hammer phenomenon”, such as quick-closing valves, back pressure impact, pump start-up or

shutdown and sudden loss of power in the system (such as power failure).

Energy storage

If the system experiences sudden power off or pump failure, Taloar pulsation damper

can maintain pressure within the system for a short time to ensure that other moving and working parts are

still lubricated and cooled, so as to protect the equipment.

Thermal expansion absorption

When liquid flows in a closed system, the liquid temperature will rise

due to friction or other reasons, the resulting liquid expansion will cause the system pressure to increase.

If the pressure exceeds safety pressure limit of the system, it will cause the pipeline to bust, valve

failure, damage to precision instruments on the pipelines. Besides, in case of system leakage, the liquid in

the pipelines may cause permanent damage to personnel and the surrounding environment. Use Taloar pulsation

damper will absorb the excess pressure caused by the thermal expansion of the liquid to ensure the safe

operation of the system.

Isolation Device

If the pressure parameters of the system are extremely important for safety

operation of the system, the instruments measuring such parameters are not allowed to contact with the fluid

in the system, Now Taloar pulsation damper can help solve this problem. In this case, the diaphragm of

Taloar pulsation damper performs an isolation function.

Choice and Maintenance

Please select the most appropriate model of pulsation damper for your system, taking into account the pressure and flow rate.

The installation location should be in close proximity to the source of potential water hammer, such as near valves or pumps.

It is essential to conduct regular inspections and maintenance to guarantee the optimal sealing and performance of the pulsation damper.

Taloar is dedicated to providing customers with the highest quality pulsation damper products, ranging from 2 inches to 12 inches, to meet their diverse requirements. If you need any special customized products, please contact us.

If you need to keep up with innovations and technological advancements in pulsation damper, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved