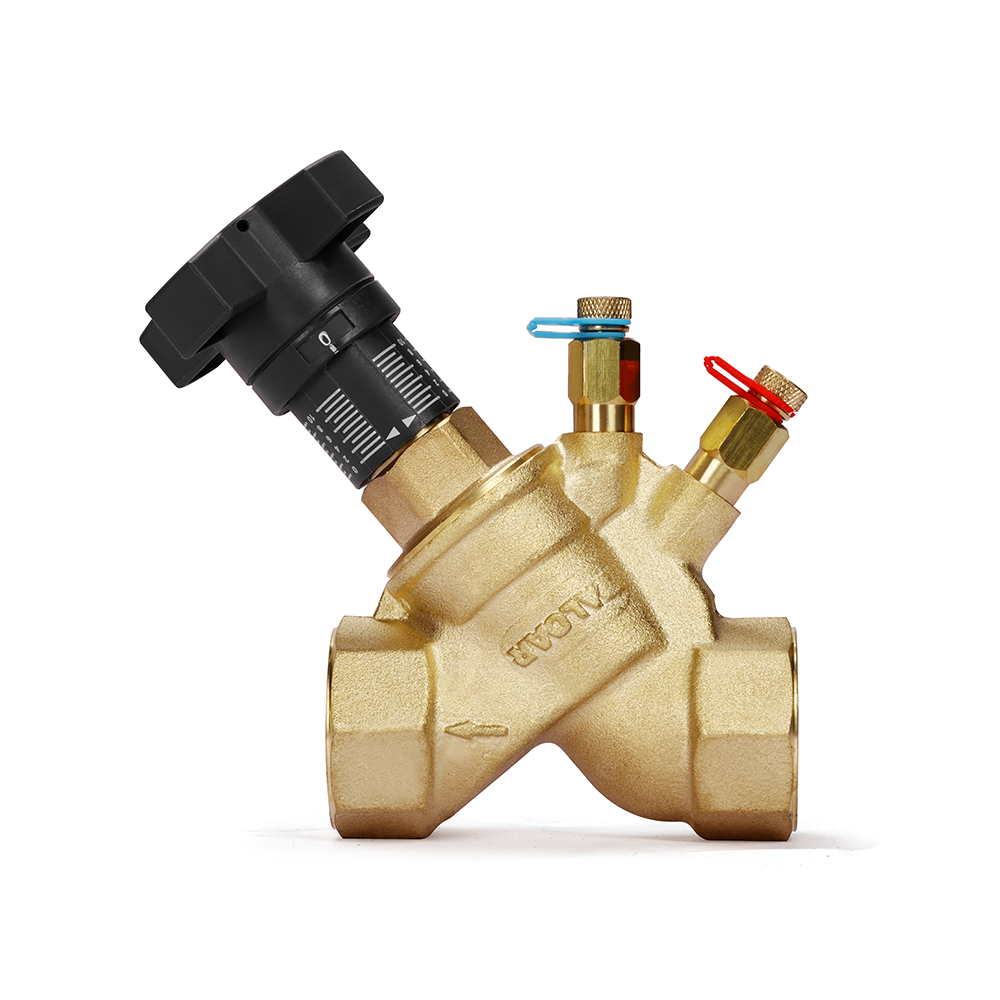

Brass threaded motorized control valves of ES100/ES150 and BL220/BL350 series apply to HVAC (heating, ventilation, and air conditioning), and building automation systems. Once the motorized control valves receive signals transmitted by computers or other devices, they can then adjust temperature, pressure and control system parameters such as flow rate and liquid level. The valves are mainly used to convey mediums such as cold water, hot water, and ethylene glycol solution.

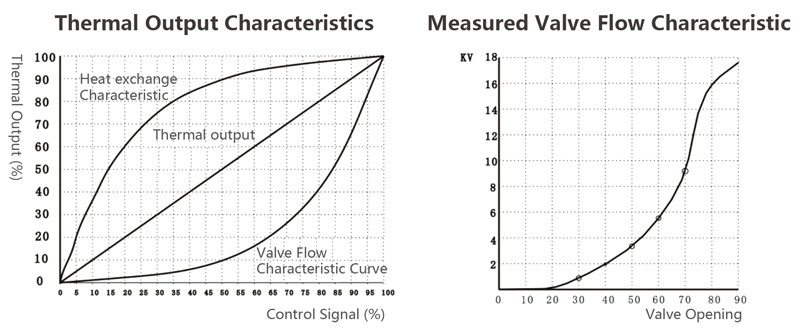

Have the equal percentage flow and the quick opening characteristics.

The control valve's body has a built-in distribution plate that helps the flow control performance more stable.

High-precision control offers precise actions.

Low power consumption and low noise.

Double O-shaped sealing design.

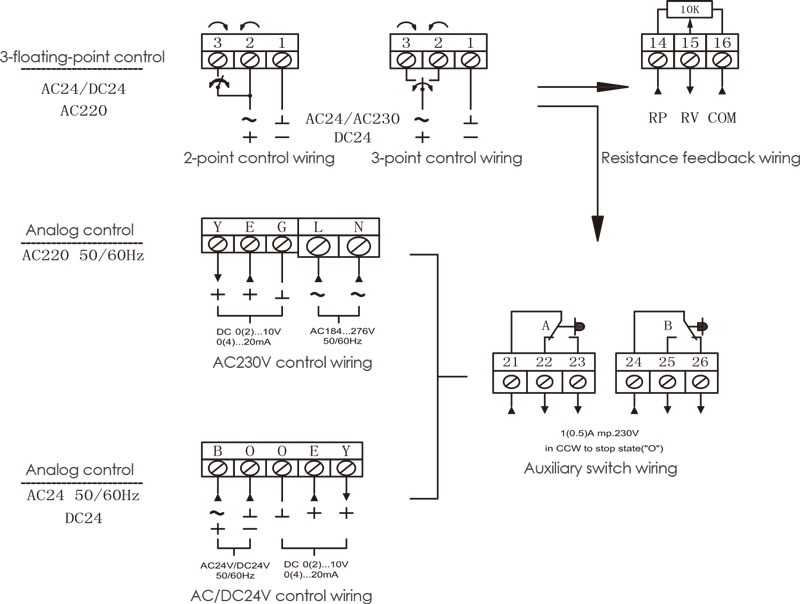

Multiple signal controls: 2-point, 3-point, DC 0-10 V, and DC 4-20 mA.

ABS shell with the advantages of small size and light weight.

Easy installation and maintenance.

Valve Type: Two-way valve,three-way valve

Material: Shell: brass; dall: stainless steel; stem: brass sealing: RPTFE

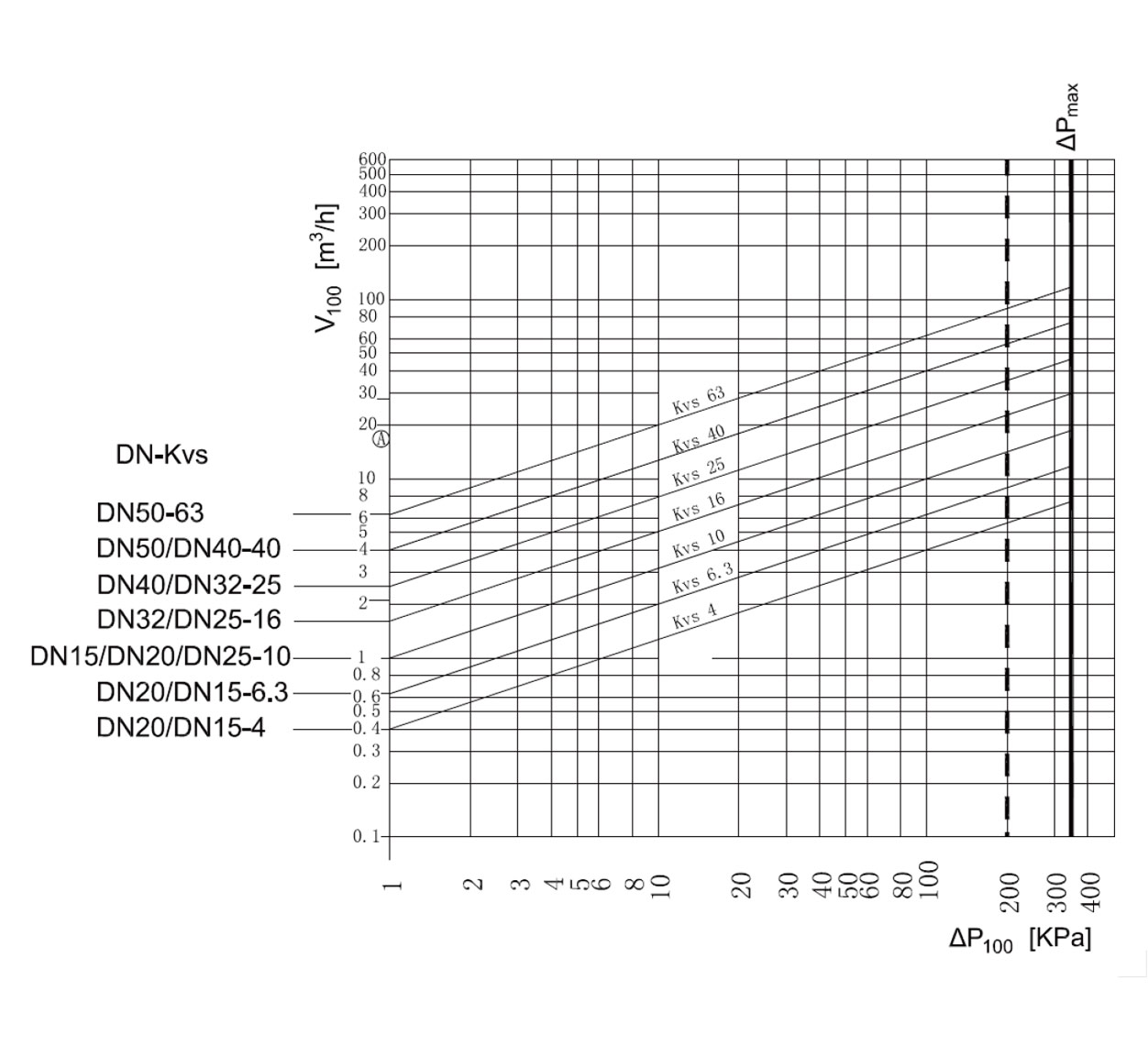

Working Pressure: 2.0 Mpa

Medium: Cold water, hot water vapor, and the aqueous solution of ethylene glycol (concentration within 50%)

Medium Temperature: -20℃ ~ 120℃

Flow Characteristic: Equal percentage curve,quick opening characteristic

Leakage Volume: Below 0.01% of kv value

End Type: BSPT or NPT threaded

| Electrical Parameters |

Rated voltage | AC/DC 24V | AC 230 V | |

| Rated voltage range | AC 19.2..28.8V | DC 21.6..26.4V | AC 184..276V | |

| Power consumption | 2.2W | 3.2W | ||

| Wire specification | 4.4A | 6.4A | ||

| Terminal specification | Maximum:2.0㎡ | |||

| Function Parameters |

Torque | 4Nm/8Nm | ||

| Suitable ball valve | 4Nm:½”~1-½”;8Nm:1-¼”~2” | |||

| Manual operation | Press the manual button and then manual operation is available. | |||

| Rotation angle | Maximum:95°, mechanically adjustable | |||

| Running time | 70 s(no load) | |||

| Noise | 45dB | |||

| Working Environment |

Appliance class | Ⅲ (low-voltage and safe) | Ⅱ(double insulated) | |

| Ingress protection | IP44 | |||

| Working temperature | -20~+50℃ | |||

| Humidity testing | 95%RH, no condensation | |||