Gate valves are a popular choice for a number of

applications in building fire protection systems, water supply and drainage, industrial and municipal pipelines.

Their superior full-open/full-close function and low fluid resistance make them an ideal solution for many

customers.

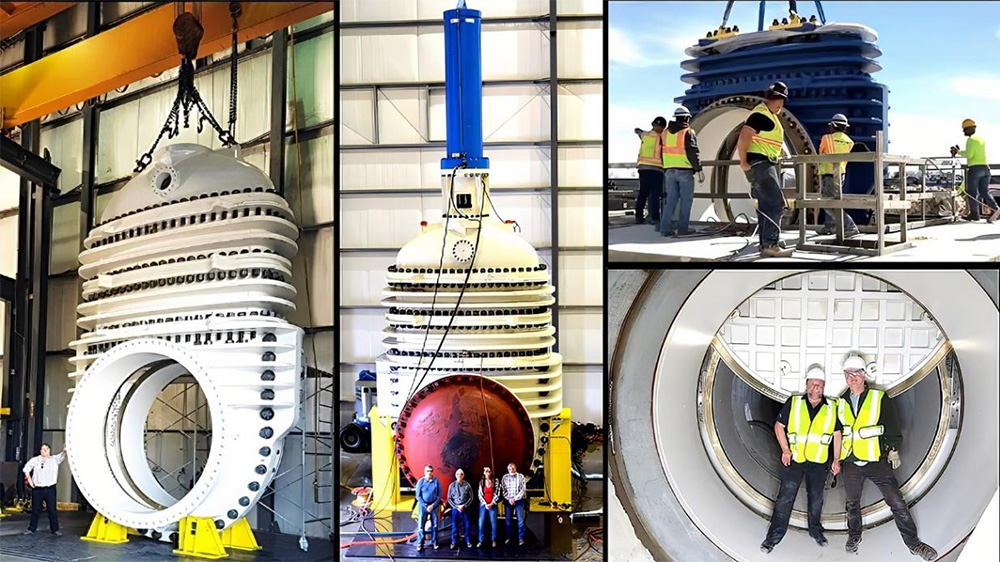

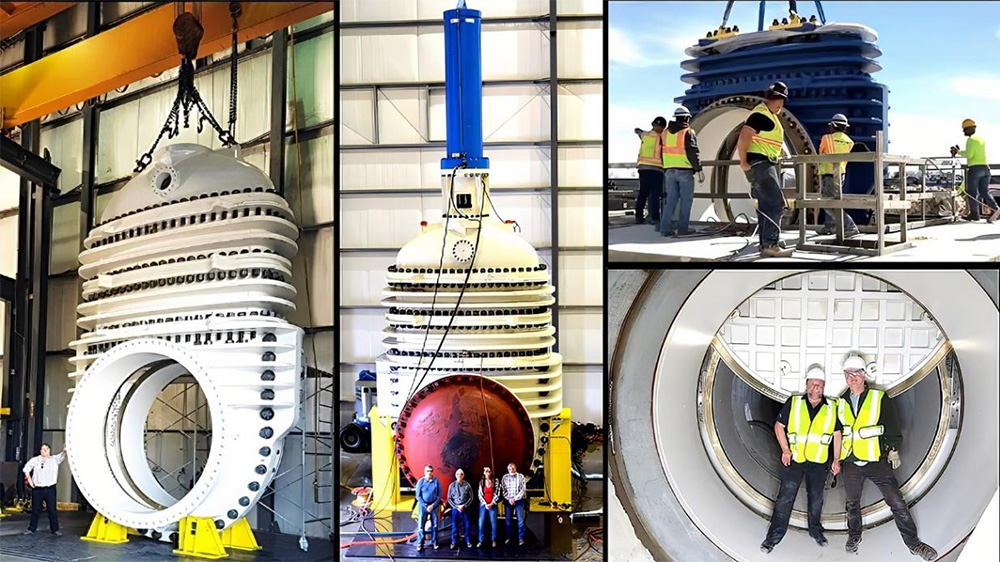

The world’s largest gate valve is Blackhall's Zero-Leakage Metal Seated Parallel Faced Gate Valve which has been

designed to last for 100 years. From this example, we can see the excellent service life of gate valves.

This article will provide a comprehensive overview of the gate valve, including its composition, operational

principles and types. Taloar, as a professional gate valve manufacturer, offers specialized services to meet

different customer requirements.

What is the gate valve?

A gate valve is a type of valve, whose operation is based on the up-and-down movement of the valve plate to control

the opening of the valve. The gate disc moves in a direction perpendicular to the fluid flow. The gate valve can

only be fully open or fully closed, which is mainly used for cutting off the pipeline.

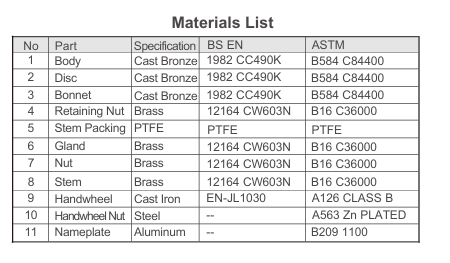

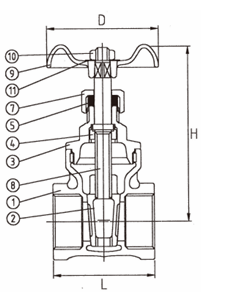

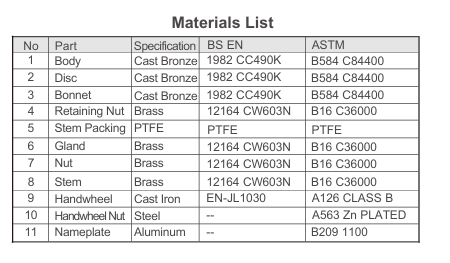

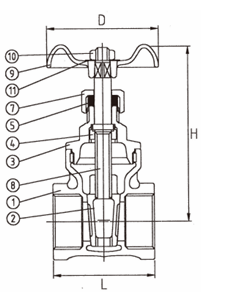

1. Gate valve part

Take the common bronze gate valve as an example: ( The one used here is a Taloar A107.)

It consists of valve body, disc, stem, seat, valve stem packing, handwheel and other parts.

2. How does a gate valve work

●

Opening process: As the valve stem rotates upwards, the valve stem drives the gate to move in the same

direction. As the gate rises, the valve seat channel expands gradually, allowing the medium to flow. Once the

gate has been fully raised to the top position, the pipeline is clear for the medium to flow freely, indicating

that the valve is fully open.

●

Closing process: The closing process involves closing the gate valve and allowing the valve stem to rotate

downwards, which in turn drives the gate plate downwards. Once the gate is in the closed position, the valve

seat channel is gradually narrowed until the gate is fully compressed on the valve seat, effectively blocking

the medium and closing the valve.

●

Sealing principle: The sealing principle of a gate valve is typically achieved through mechanical pressure

between the gate and seat. When the gate is pressed against the valve seat, a seal is formed to prevent any

leakage of the medium.

Gate valve types

There are a variety of classification standards for gate valves. This article will introduce you to the most common

types of classification:

1. Stem structure:

●

Rising stem gate valve: The

valve stem moves up and down with the disc during the opening and closing process, and the threads of the valve

stem are outside the valve body. This design is easy to observe the opening and closing status of the valve, but

takes up more space.

Iron gate valves MG670-R (Rising)

●

Non rising stem gate

valve:The valve stem does not move up and down with the disc and the stem threads are located inside the

valve body. This design saves space, but it is not possible to judge the opening and closing status of the valve

directly from the stem.

Iron gate valves MG670-N (Non-rising)

2. Valve body material:

●

Bronze gate valve: Bronze is a

copper-based alloy, usually containing elements such as tin and zinc, which has

good corrosion and wear resistance. Bronze is particularly suitable for use in media such as seawater, fresh

water and oil. It is slightly less strong than brass and steel, but more durable and corrosion resistant.

Bronze gate valves A107

●

Brass gate valve: Brass is an

alloy of copper and zinc, with a high zinc content and relatively high hardness and strength compared to bronze.

Brass is easy to process into a variety of complex shapes, the price is more economical. Brass gate valves are

suitable for water, gas, oil and other non-corrosive or weakly corrosive media, but seawater corrosion

resistance is worse than bronze.

Brass gate valves A103

●

Cast iron gate valve: Cast

iron is an alloy of iron, carbon and silicon and is commonly used in the manufacture

of low cost valves. Cast iron has better abrasion resistance and is suitable for handling non-corrosive media

such as water and oil. Cast iron gate valves are cheaper to manufacture and are suitable for lower pressure

systems.

●

Ductile

cast iron gate valve: Ductile cast iron is based on normal cast iron by adding magnesium, cerium and

other elements so that the graphite in the iron is spherical, which improves the toughness and strength of the

cast iron. Compared with ordinary cast iron, ductile iron has better tensile strength and toughness, and can

withstand greater pressure and impact. While retaining the wear resistance of cast iron, it has better corrosion

resistance.

Ductile iron gate valves FG970-EN

3. Connection

●

Flanged gate valve: It is the most common connection method, suitable for large diameter and high pressure

occasions. The valve body and pipeline are fastened by flanges and bolts, with good sealing and easy

disassembly.

●

Threaded gate valve: This is suitable for small diameter pipework, easy to install. Threaded gate valves can be

divided into internal and external threaded connections, commonly used in domestic and industrial low-pressure

occasions.

●

Solder-end gate valve: It is suitable for high pressure, high temperature and some systems with high tightness

requirements. Solder-end gate valves have good sealing performance, but maintenance and replacement is not

convenient.

●

Grooved-end gate valve: It is mainly used for quick disassembly and assembly, commonly used in food, beverage,

pharmaceutical and other industries that require quick cleaning.

As a professional gate valve supplier, Taloar is committed to providing the most suitable gate valves for each

customer. Welcome to contact us for any of the gate valves mentioned above.

If you need to keep up with innovations and technological advancements in gate valves, Taloar will support you! For

more details, please contact sales@taloar.com or WhatsApp 008618112507128.