Check valves are a vital component in modern fluid systems, preventing backflow and ensuring smooth operation. This article will provide a comprehensive introduction to check valves, including their definition, operating principle, classification, application scenarios, advantages and disadvantages, and maintenance, so that readers can better understand and apply this important fluid control device.

Definition and Working Principle

Check valve, also known as non-return valve or one-way valve, is a type of automatic valve that uses the fluid's own pressure or flow rate changes to open and close, preventing reverse flow. Once the specified medium pressure or flow rate is reached, the check valve will automatically open, allowing the medium to flow in the desired direction. Conversely, when the medium pressure or flow rate is reduced, the check valve will automatically close to prevent the medium from flowing backwards. This mechanism guarantees the optimal functioning of the fluid system, preventing potential damage or safety incidents caused by backflow.

Classification and Structure

There are numerous varieties of check valves, classified according to their distinctive structural characteristics and operational principles. Taloar check valves can be primarily categorized into the following types:

Bronze check valves C107

½ ″ - 4 ″

PN20/300PSI/Class150

Horizontal Swing

BSEN12288, Threaded Ends Comply to BS21 or ANSI 2.1

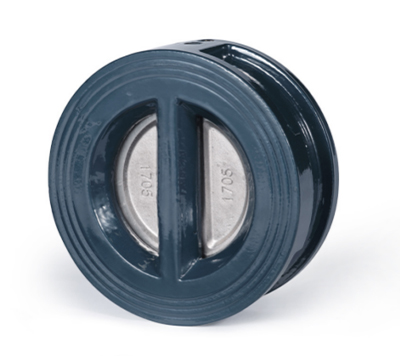

Dual plate check valves CF900-X

2 ″ - 48 ″

PN16/235PSI/Class125

Wafer Style, Rubber Seat, Spring Actuated

Design to EN12334:2001/API594

Flange Dimension EN1092-2, ANSI B16.1 Class 125

Iron check valves CF670-Y

Horizontal Swing Check Valves

2 ″ - 24 ″

PN16/235PSI/Class125

Horizontal Swing, Bronze Seat

Design to BS5153 and MSS SP-71

Flange Dimension to EN1092-2, ANSI B16.1 Class 125

Ductile iron check valves CF970-Y

2 ″ - 24 ″

PN16/235PSI/Class125

Horizontal Swing, Bronze Seat

Design to BS5153 and MSS SP-71

Flange Dimension to EN1092-2, ANSI B16.1 Class 125

Ductile iron silent check valves CF970-V

Ductile iron silent check valves

2 ″ - 16 ″

PN16/235PSI/Class 125

Globe Style Center-Oriented, Spring Actuated

Flange Dimension EN1092-2, ANSI B16.1 Class 125

Ductile iron silent check valves CF970-B

Ductile iron ball Non-Return valves

2 ″ - 24 ″

PN16/235PSI/Class125

Spherical Rubber Disc

BSEN1074-3 and BSEN12334

Flange Dimension EN1092-2, ANSI B16.1 Class 125

Non-slam check valves NC500

Non-slam check valves

2 ″ - 20 ″

Smooth action, without impact

Easy regulating and maintenance

Excellent and reliable sealing performance

Controllable opening and closing speed

Built-in strainer, to prevent the piping system from blocking

Non-slam check valves NC300

2 ″ - 12 ″

Smooth action, without impact

Small volume and light weight

Easy regulation and maintenance

Excellent and reliable sealing performance

Separately controllable opening and closing speed

Built-in strainer, to prevent the guide piping system from being blocked

Application Scene

Check valves are a highly versatile product, used in a wide range of fields thanks to their unique one-way flow control function.

Advantages, Disadvantages and Maintenance

Advantages:

Disadvantages:

Maintenance:

It is essential to regularly assess the sealing performance and opening and closing flexibility of the check valve to guarantee the optimal condition of the valve.

It is necessary to clean the interior of the valve to prevent clogging and wear.

It is crucial to recognize the significance of check valves as a vital component in fluid systems. By selecting the appropriate type of check valve and conducting regular maintenance and inspections, it can guarantee the stable operation of the fluid system and prevent equipment damage or safety incidents caused by backflow. As professional check valve manufacturers, Taloar always commits to innovation and quality assurance to ensure that our check valves will continue to expand their performance and range of applications. This will provide our customers with even more reliable protection for the safe and efficient operation of fluid systems.

If you need to keep up with innovations and technological advancements in check valves, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved