Balance valve is a kind of valve with the special function, which plays a dynamic and static balance adjustment role in the hydraulic working conditions. This article will do a detailed introduction to the balance valves.

Definition

In some industries, the balance valve is used to regulate pressure and flow in pipelines or containers. This is due to the fact that different parts of the system may experience significant pressure or flow differences. The valve is installed to ensure a consistent pressure or flow rate across the entire system.

Classification

Balance valves can be classified into two main categories: static balance valves and dynamic balance valves.

1. Static Balance Valves:

The static balance valve works to change the resistance of fluid flowing through valves by regulating opening that is related to the gap between the valve disc and seat. In this way, flow is regulated. That is, the balance valve serves as a throttle control with adjustable local resistance. For non-compressible fluid, the flow formula is shown as follows:

Q=KV×√(ΔP)

In the formula, Q stands for flow passing through the balance valve (m³/h); Kv stands for valve resistance coefficient, adjustable; ΔP stands for differential pressure (bar) between both ends of valve.

Balance valve resistance coefficient (Kv) means the flow (m³/h) through balance valve when the differential pressure between both ends of valve is 1 bar (1.02 kgf/cm²). When the opening of the balance valve remains unchanged, Kv will remain the same. That is, Kv depends on the opening of the valve. If Kv values are known under different opening conditions beforehand, flow will be figured out by measuring pressure differential between both ends of the valve. Therefore, the balance valve can be used as the throttle control to regulate flow quantitatively.

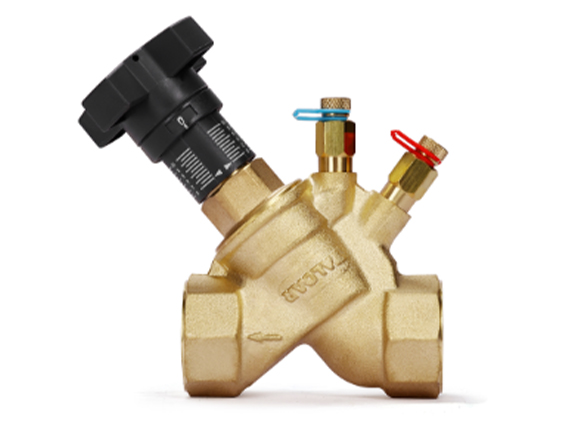

Taloar small-sized brass balance valve adopts low-resistance Y-shaped structure, and its orifice plug is of V-shaped design for better linear regulation. Flow measuring fittings on both ends feature good self-sealing performance and easy adjustment. The highly precise valve disc and favorable sealing performance ensure measurement precision and persistence.

Taloar ductile iron flow balance valve adopts low-resistance Y-shaped structure, the shell is coated with epoxy resin. Flow measuring fittings on both ends feature good self-sealing performance and easy adjustment. The highly precise valve core and favorable sealing performance ensure measurement precision and persistence.

2. Dynamic Balance Valves:They can be divided into auto-flow balance valves, dynamic differential pressure control valves and pressure independent control valves.

Function and application:

Balance valves serve three key functions: load holding, load control and safety. They are used in a diverse range of applications.

The balance valve is typically employed in large-scale heating and air conditioning water systems. It effectively ensures the static hydraulic and thermal balance of the pipe network, eliminating the imbalance between the hot and cold levels. It can adapt to system quality or quantity adjustments and achieve energy savings. Additionally, it is a popular choice in the water treatment and industrial refrigeration sectors.

Installation

When installing the balance valves, please note the following points:

Precautions

It is not possible to use a balance valve in a system with centralized regulation to change the volume of water in response to demand. This is because such a system will undergo changes in hydraulic condition, which will affect the performance of the balance valve.

In selecting a balance valve, it is important to consider not only the pipe diameter, but also the actual demand and system conditions. The balance valve should be selected with the same nominal pipe diameter specifications.

It is possible to adjust the parameters of the balance valve at any stage during the process. However, it is important to avoid making arbitrary changes to the balance valve opening, in order to maintain the stability and efficiency of the system.

The balance valve is a vital piece of fluid control equipment, playing an indispensable role in numerous industrial sectors. By precisely regulating the flow and pressure, the balance valve ensures the stable operation of the system, improves the efficiency of energy use, and also guarantees the safety and reliability of the equipment.

As science and technology advance and industrial development continues, the design, manufacture and application of balance valves are also evolving. Taloar is responding to market changes by transforming traditional balance valves into intelligent balance valves. This innovation is enhancing the performance, convenience and scope of application of balance valves. Taloar will continuously launch launching new products.

If you need to keep up with innovations and technological advancements in balance valves, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved