In modern industry and daily life, the use of automatic water level control systems is becoming more widespread, not only improving efficiency but also reducing the need for manual monitoring. As the core component of automatic water level control, the float valve's accuracy and reliability are crucial to the stability of the whole system. In this paper, the structure, working principle, classification and application of float valves will be introduced in detail.

What is Float Valve?

The float valve is a commonly used liquid control valve because it is simple, stable and reliable. It adopts the float ball as the power device to open and close the valve, which effectively achieves the purpose of automatic control.

Float valve is mainly composed of valve body, seat, stem, piping, diaphragm, fasteners and springs, float ball, lever system, gaskets and so on.

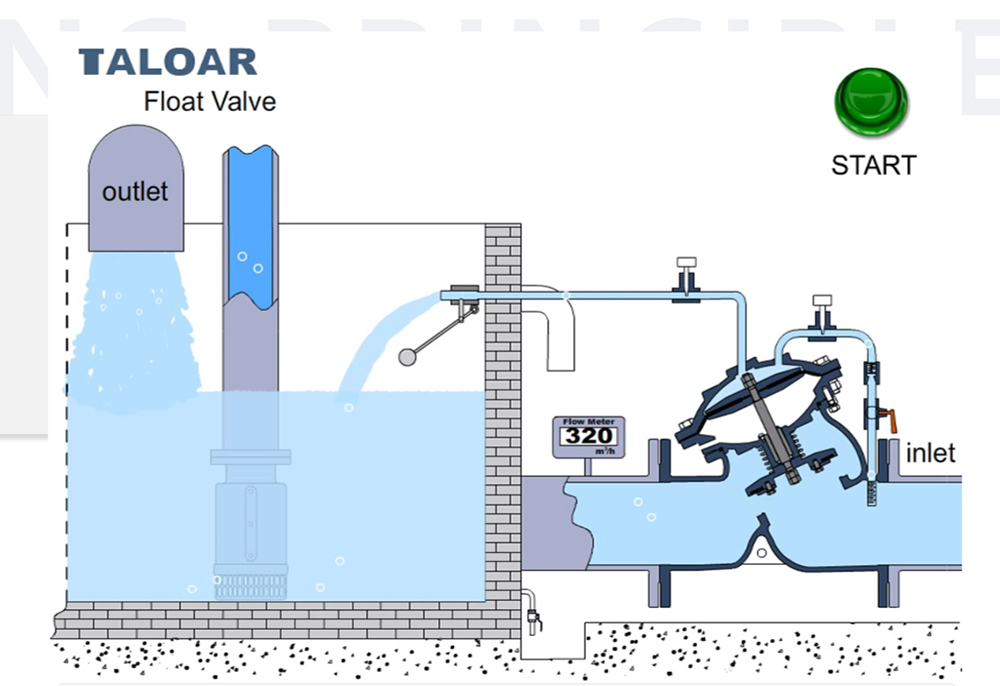

Working Principle of Float Valves (Here take Taloar’s FM500 as an example.)

Diaphragm float valve is a fluid controlled valve. It keeps the water level in the storage tank at a relatively stable level. The float control switch is installed in the water tank when the water level is high and is connected to the basic valve through the pipeline. When the water level rises and exceeds the maximum limited level, the float pilot valve will fully close and the basic valve automatically closed. When the water level drops to the lowest limited level, the float pilot valve will be fully open, the basic valve will automatically open for water supplement until the level in the water storage tank is controlled within the stable ideal range

Types of Float Valves

There are numerous ways to categorize float valves. This article focuses on the classification of float valves according to the material used.

Float Valve FM300

Ductile Iron

2 ″ - 12 ″

Precise and repeatable water level control

Small volume and light weight

Reliable full hydraulic control

eliable tightness

Large flow

Built-in strainer, to prevent the guide piping system from being blocked

Float Valve FM500

2 ″ - 20 ″

Precise and repeatable water level control

Ideal slow opening and closing functions

Reliable full hydraulic control

Reliable tightness

Large flow

Built-in strainer, to prevent the piping system blocking

Float Valve FM300S

2 ″ - 12 ″

All stainless steel body and guide piping fittings

Precise and repeatable water level control

Small volume and light weight

Reliable full hydraulic control

Reliable tightness

Large flow

Built-in strainer, to prevent the guide piping system from being blocked

Application

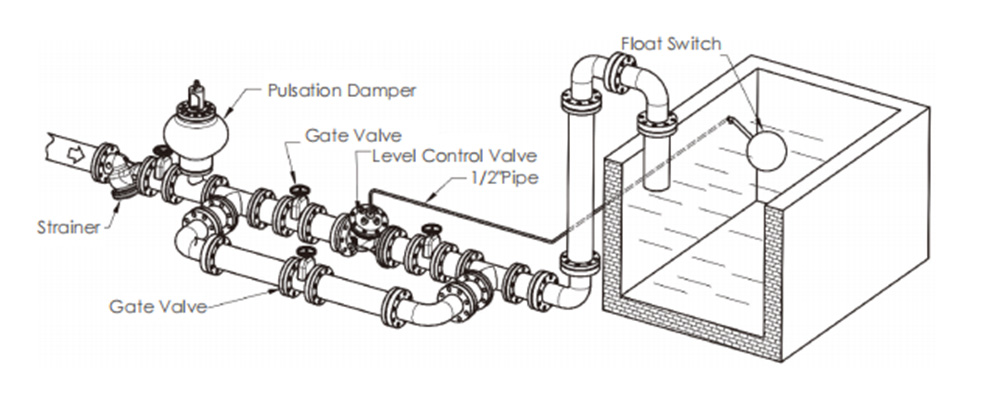

Installation

Install the valve and float control switch as shown in the diagram. The float control switch should be installed on the relative static water surface at the outlet of the connected pipeline and positioned at the desired water level.

The outlet should be as far away from the float controller as possible (recommended: >5 m), otherwise, the level fluctuation generated by the water outlet may cause frequent valve opening and closing, generate noise and thus shorten the service life of the valve.

As a professional valve manufacturer, Taloar is dedicated to providing every customer with the highest quality float valves. Taloar float valves offer precise, repeatable water level control, ideal slow opening and closing functions, reliable fully hydraulic control, dependable tightness, high flow rates, and built-in strainers to prevent blocking of the piping system.

If you need to keep up with innovations and technological advancements in float valves, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved