As one of the most important actuators in this field, electric valves undertake the core task of fluid control. Electric valves are a key component in modern industrial systems, with applications across a range of industries, including petroleum, chemicals, electric power, metallurgy, and water treatment. The stability and reliability of these components directly impact production efficiency and safety. This paper will examine the operational principles, categorization, selection, and application of electric control valves.

Fundamental operational principle of electric valves

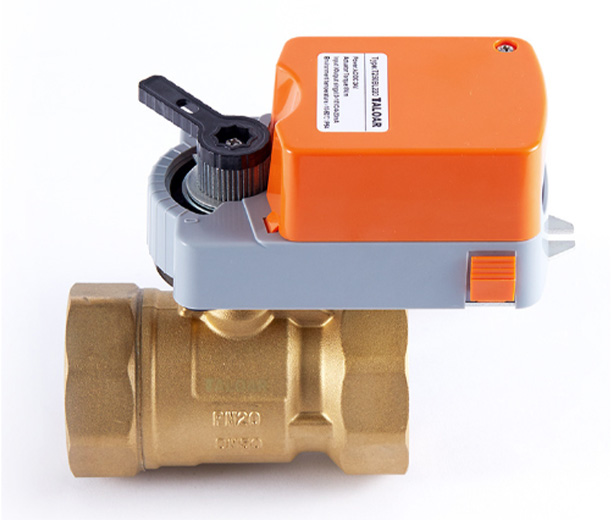

Electric valves are driven by an electric actuator which opens and closes the valve parts and then drives the opening and closing parts in the valve body for up and down or rotary movement to achieve opening, closing or adjustment of the fluid.

Classification of electric valves

Electric valves are classified in a variety of ways, according to factors such as structure, function, opening and closing methods, and so on. They can be divided into the following categories:

Classification by structure:

Classification by function:

Classification by opening and closing method:

Types of Taloar electric valves

Taloar's electric butterfly valves are available in two models, differentiated by the type of actuator:

HB950-ET/RM and HB950-EH/RH.

Features of electric butterfly valves:

Taloar offers a range of motorized control valves, including the ES/BL series, UL/AF series and VF/NL series, which are suitable for use in HVAC (heating, ventilation, and air conditioning), and building automatic control systems. Once the motorized control valves receive signals transmitted by computers or other devices, they can then adjust temperature, pressure and control system parameters such as flow rate and liquid level. The valves are mainly used to convey mediums such as cold water, hot water, and ethylene glycol solution.

It also includes the range of pressure-independent control valves, including the TB300, TS500 and F535E models. Pressure independent control valve allows presetting at the maximum flow, pressure-independent balancing and electric control. Flow control is only related to the opening of the electric actuator, regardless of system pressure differential fluctuation. TB500 valve authority reaches 100%. The actual and ideal flow characteristic curves keep consistent provides precise and fast control, reduces actuator operating frequency, bringing stable energy saving effect.

3. Two-Way Pressure-Independent Balance Valves

Taloar’s two-way pressure-independent balance valve integrates electric on/off control and pressure-independent balancing. The valve is mainly used for on/off control of cold and hot water in fan coils at the end of the HVAC system and for pressure-independent balancing. In case of pressure fluctuation within the system, it works to keep flow unchanged while the valve is power on, especially in the variable flow system with excessively fluctuating load. It features strong immunity against interference, brings optimal temperature with the best indoor comfort effect.

Taloar FC200 series and FC500 series motorized two-way valves are mainly used to control the opening and closing of cold water and hot water in the terminal of the fan coil units of the air conditioning systems in order to provide a comfortable room temperature. When needed, the motorized valve will automatically turn on after receiving the control signal transmitted from the room temperature controller, then cool or warm the room as required. When temperature reaches the specified value, the room temperature controller will automatically cancel the transmitting signal, and the spring within the motorized valve will force it to turn off and bring it back to the original pre-set value.

Motorized control valve applications

The development trend of electric valves

As industrial automation becomes more sophisticated, electric valves are evolving to become more intelligent, networked and modular.

Electric valves are a crucial component of industrial automation systems. Their technological advancement and broader application are driving significant growth in modern industry. As technology and applications continue to evolve, motorized control valves will become an increasingly important factor in driving industrial development in a more efficient, intelligent and environmentally friendly direction.

If you need to keep up with innovations and technological advancements in electric valves, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved