Precise and repeatable water level control

Ideal slow opening and closing functions

Reliable full hydraulic control

Reliable tightness

Large flow

Built-in strainer, to prevent the piping system blocking

Precise and repeatable water level control

Ideal slow opening and closing functions

Reliable full hydraulic control

Reliable tightness

Large flow

Built-in strainer, to prevent the piping system blocking

If the optional check feature is selected, when the back pressure is generated, the return fluid will enter the air chamber to close the valve to prevent the fluid from back flow.

Body/Bonnet: Ductile Iron/Stainless Steel

Disc & Stem: Stainless Steel

Piping: Bronze/stainless Steel/Rubber Hose

Diaphragm: NBR

Fasteners and Springs: Stainless Steel

175PSI/235PSI/350PSI

10Bar/16Bar/25Bar

ANSI / BSEN / ISO / DIN

0°C~100°C normal temperature water

Controller: ½″ float valve

Pressure Regulator Material: Bronze/Stainless Steel

Valve figure number/size/pressure grade/connecting end type/other optional accessories

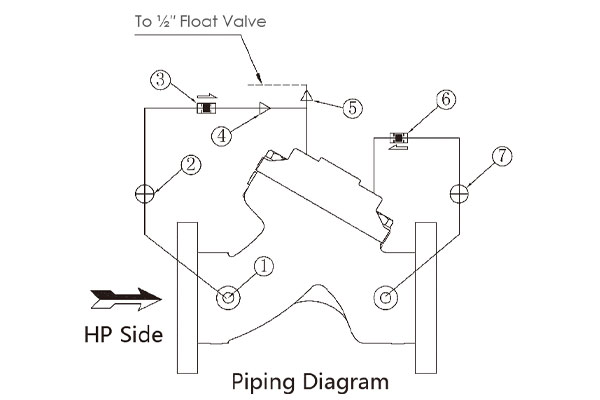

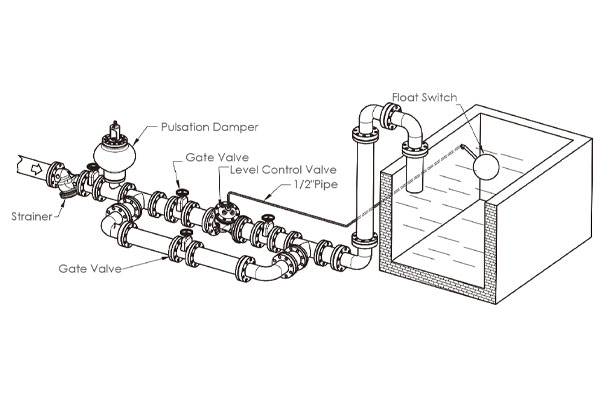

Note: In valve installation, it is strongly suggested that sufficient space should be left for easy maintenance in the future. A strainer shall be mounted in front of the valve to prevent foreign matters from blocking the valve.

① Strainer

② Ball Valve

③ Check Valve (Optional)

④ Needle Type Regulating Valve

⑤ Needle Type Regulating Valve

⑥ Check Valve (Optional)

⑦ Ball Valve (Optional)

Install the valve and float control switch as shown in the diagram. The float control switch should be installed on the relative static water surface at the outlet of the connected pipeline and positioned at the desired water level.

The outlet should be as far away from the float controller as possible (recommended: >5 m), otherwise, the level fluctuation generated by the water outlet may cause frequent valve opening and closing, generate noise and thus shorten the service life of the valve.

Copyright © TALOAR All Rights Reserved