PN16/235PSI/Class125

Horizontal Swing, Bronze Seat

Design to BS5153 and MSS SP-71

Flange Dimension to EN1092-2, ANSI B16.1 Class 125

CF970-Y

PN16/235PSI/Class125

Horizontal Swing, Bronze Seat

Design to BS5153 and MSS SP-71

Flange Dimension to EN1092-2, ANSI B16.1 Class 125

| Hydraulic Pressure Test | |

| Body | 2.4Mpa/24Bar |

| Seat | 1.76Mpa/17.6Bar |

| Pressure Ratings |

| 1.0 Mpa at 180°C |

| 1.6 Mpa at -10°C-120°C |

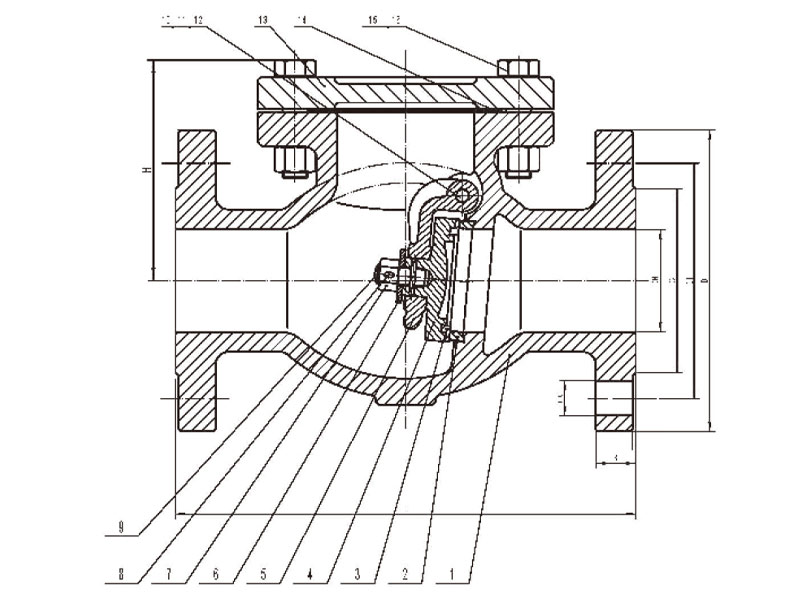

| No | Part | Specification | BS EN | ASTM |

| 1 | Body | Ductile Iron | BSEN 1563 | A536 65-45-12 |

| 2 | Seat Sealing Ring | Cast Bronze | 1982 CC491K | B62 |

| 3 | Disc Sealing Ring | Cast Bronze | 1982 CC491K | B62 |

| 4 | Disc | Ductile Iron | BSEN 1563 | A536 65-45-12 |

| 5 | Support | Ductile Iron | BSEN 1563 | A536 65-45-12 |

| 6 | Gasket | Steel | BSEN 10087 | Steel A307 |

| 7 | Nut | Steel | BSEN 10087 | Steel A307 |

| 8 | Safety Pin | Stainless Steel | BSEN 10088-1 | AISI 304 |

| 9 | Screw | Steel | BSEN 10087 | Steel A307 |

| 10 | Support Pin | Brass | 12164 CW603N | B16 |

| 11 | Gasket | Steel | BSEN 10087 | Steel A307 |

| 12 | Safety Pin | Stainless Steel | BSEN 10088-1 | AISI 304 |

| 13 | Bonnet | Ductile Iron | BSEN 1563 | A536 65-45-12 |

| 14 | Bonnet Gasket | Graphite | -- | -- |

| 15 | Bolt | Steel | BSEN 10087 | Steel A307 |

| 16 | Nut | Steel | BSEN 10087 | Steel A307 |

| mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| In | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| L | 203 | 216 | 241 | 292 | 330 | 356 | 495 | 622 | 699 | 787 | 914 | 914 | 1016 | 1219 | |

| H | 112 | 132 | 141 | 162 | 192 | 211 | 270 | 316 | 357 | 560 | 589 | 645 | 702 | 812 | |

| D | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 | 640 | 715 | 840 | |

| D1 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | |

| D2 | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 | 429 | 480 | 548 | 609 | 720 | |

| B | 20 | 20 | 22 | 24 | 26 | 26 | 30 | 32 | 32 | 36 | 38 | 40 | 42 | 48 | |

| n-d | 4-19 | 4-19 | 8-19 | 8-19 | 8-19 | 8-23 | 12-23 | 12-28 | 12-28 | 16-28 | 16-31 | 20-31 | 20-34 | 20-37 | |

| Weight | Lbs | 26 | 39 | 47 | 82 | 124 | 160 | 271 | 443 | 642 | 935 | 1195 | 1446 | 1835 | 2778 |

| Kg | 12 | 18 | 21 | 37 | 56 | 72 | 123 | 201 | 291 | 424 | 542 | 656 | 832 | 1260 | |

Copyright © TALOAR All Rights Reserved