In the fluid control system, the hydraulic control valve is an important core component and Taloar’s hydraulic control valves have excellent performance and reliable quality. Whether it is water irrigation, municipal water supply or fluid control in industrial production, the right hydraulic control valve is the key to ensuring the stable operation of the system.

In terms of structural design, it is based on advanced hydraulic principles and carefully crafted in every detail. The robust and durable valve body is able to withstand different pressure environments. It can operate stably, whether in high-pressure industrial water transfer or low-pressure irrigation. The internal spool and seat are precisely matched to effectively prevent leakage and ensure accurate water flow control.

In terms of functionality, these hydraulic control valves have excellent control capabilities. For flow control, they can be precisely adjusted over a wide range according to actual requirements to meet a variety of complex working conditions. For pressure control, they can automatically compensate for pressure fluctuations in the system to prevent damage to pipework and equipment caused by high or low pressure.

This article will take Taloar’s hydraulic control valves as examples and discuss different types of hydraulic control valves and their applications. Understanding the differences between these valves can help you select the right valve for your specific application scenario and ensure effective flow control.

Taloar’s hydraulic control valves covers a wide variety of types. Traditional hydraulic control valves, with their exquisite craftsmanship and reliable quality, can precisely regulate water flow and work stably under various pressure and flow conditions. For example, in some emergencies that require a quick response, specially designed valves can realize opening and closing actions in a short time to ensure system safety. A full range of specifications is now available for different pipe diameters and flow requirements.

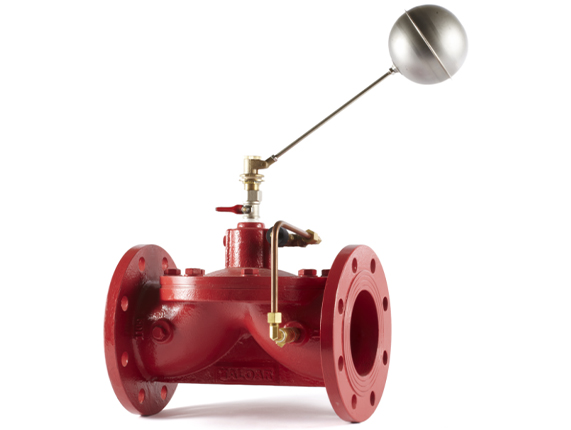

This is a widely used hydraulic control valve. It is mainly used for pools, water towers and other level control applications. When the water level in the pool drops, the float ball drops with it, and the valve opens through the lever and other transmission devices, and the water flows into the pool; when the water level rises to the set height, the float ball floats up, driving the valve to close, effectively maintaining the stability of the liquid level. It is characterized by precise water level control, sensitive operation and good sealing performance, which can effectively prevent water leakage.

In piping systems, non-slam check valves can prevent the backflow of media and cushion the closure. For example, at the pump outlet, when the pump stops working, the backflow of the medium will cause water hammer phenomenon, Taloar’s non-slam check valves use its own hydraulic principle to make the valve close slowly to minimize the effects of water hammer, protecting the piping system, pumps and other equipment from damage. These valves are widely used in municipal water supply, building water supply and drainage systems and are compact and highly reliable.

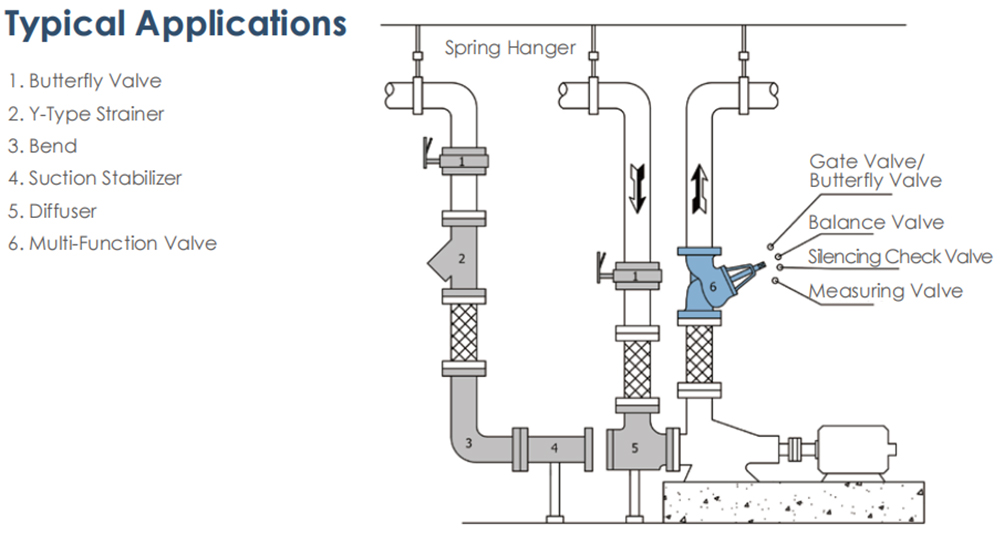

The multi-functional valve can perform more functions on the same valve body. First, it can be used as silent check valve or on-off valve. Apart from that, it can also be a balance valve.

Besides, it has two connections points reserved for testing.

A unique V-shaped seat is used in

the valve therefore the valve has good regulating performance. Due to the design features, the valve can be

maintained in the pipelines without special tools, without the need for removing the valve from the

pipeline.

The multi-function valve integrates the functions of butterfly valve , balance valve,

silent check valve and measuring valve. The use of the multi-functional valve can shorten installation time,

reduce installation space, and save installation cost (including hardware

cost, labor cost, etc.).

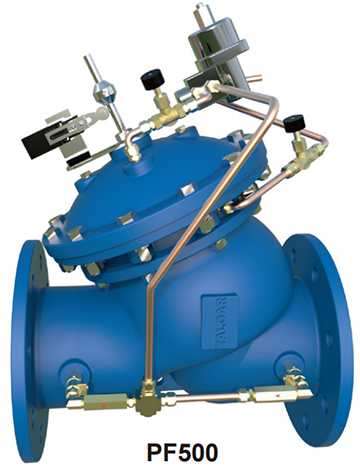

The pump control valve is installed at the pump outlet, controlled by the guide pipe to eliminate the impact

of the fluid on the pipelines during pump start-up or power-off.

At pump start-up, the control

valve is in closed state. After the start-up, the electromagnetic control switch is powered on; the valve

will open gradually; the pressure in the pipeline rises slowly until the working head of the pump is

reached.

When the pump receives the shutdown signal, the electromagnetic control switch will

power off; the valve will start to close gradually; the flow in the pipeline gradually reduces while the

water pump is still working. When the valve is fully closed, the limit switch installed on the valve will

form an electronic interlocking relationship with the pump to cancel the pump start-up command, the pump

stops.

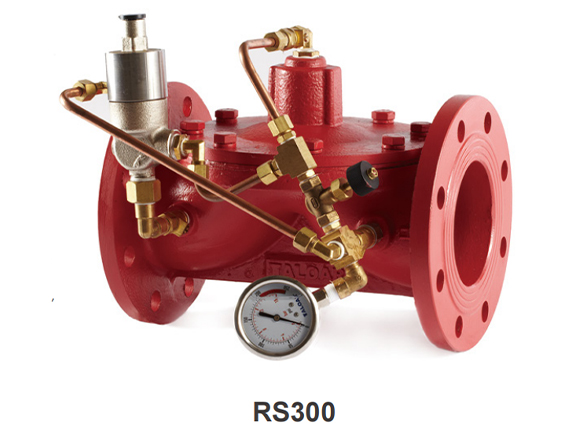

Pressure relief valve/pressure holding/back pressure valve is a fluid controlled valve. It can maintain

pressure of the upstream pipe by regulating the diaphragm of the pressure regulator. The valve can be used

in pressure relief, pressure holding and back pressure impact occasions.

During operation, the

valve senses inlet pressure of the valve by the pressure regulator to control the valve to open or to close.

When inlet pressure exceeds the set value, the valve will open quickly to maintain pressure in the

pipelines. After pressure release, the valve will close slowly to prevent water hammer impact.

In addition, there are pressure reducing valves, solenoid control valves/ electronic hydraulic control valves, differential pressure relief valves, backflow prevention devices, suction diffusers, pulsation dampers and many other types of hydraulic control valves, each with different design characteristics and applications.

The hydraulic speed control valve focuses on precise control of water flow velocity. In processes where water velocity is a strict requirement, such as fine chemical production or specific laboratory environments, it ensures that the water velocity is stabilized at the set value, guaranteeing the accuracy of production and experiments.

These hydraulic control valve products, have gone through rigorous quality testing and verification of actual working conditions. Taloar adheres to the professional attitude and technology, strict control of product quality to guarantee that each hydraulic control valve has gone through a series of testing processes with long-term stable performance. Taloar is committed to providing you with high-quality, high-performance hydraulic control valve solutions, to help you improve engineering efficiency, reduce maintenance costs, for your engineering fluid control escort.

If you need to keep up with innovations and technological advancements in hydraulic control valves, Taloar will support you! For more details, please contact sales@taloar.com or WhatsApp 008618112507128.

Copyright © TALOAR All Rights Reserved