Separately controllable opening and closing speed

Manual operated electromagnetic control switch available.

Excellent and reliable sealing performance

Easy operation and maintenance

Built-in strainer, to prevent the guide piping system from blocking

Separately controllable opening and closing speed

Manual operated electromagnetic control switch available.

Excellent and reliable sealing performance

Easy operation and maintenance

Built-in strainer, to prevent the guide piping system from blocking

When the pump receives the shutdown signal, the electromagnetic control switch will power off; the valve will start to close gradually; the flow in the pipeline gradually reduces while the water pump is still working. When the valve is fully closed, the limit switch installed on the valve will form an electronic interlocking relationship with the pump to cancel the pump start-up command, the pump stops.

Body/Bonnet: Ductile Iron/Stainless Steel

Disc & Stem: Stainless Steel

Piping: Bronze/Stainless Steel/Rubber Hose

Diaphragm: NBR

Fasteners and Springs: Stainless Steel

175PSI/235PSI/350PSI

10Bar/16Bar/25Bar

ANSI / BSEN / ISO / DIN

0°C~100°C normal temperature water

Voltage Range: 110 V, 50~60 Hz, AC or 220 V, 50-60Hz, AC

Body Material: Brass/Stainless Steel

Valve figure number/size/pressure grade/connecting end type/voltage range/other optional accessories

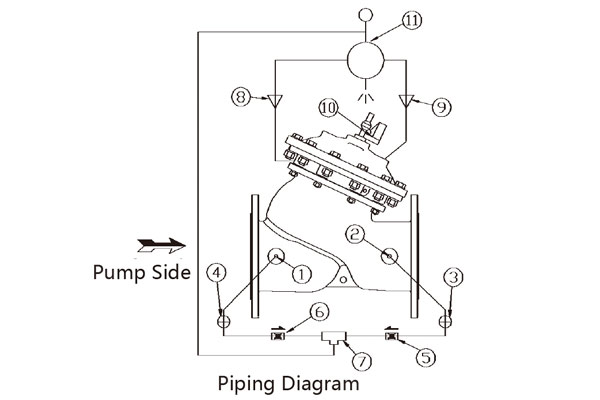

Note: In valve installation, it is strongly suggested that sufficient space should be left for easy maintenance in the future. A strainer shall be mounted in front of the valve to prevent foreign matters from blocking the valve.

① Strainer

② Strainer

③ Ball Valve

④ Ball Valve

⑤ Check Valve

⑥ Check Valve

⑦ Three-Way Pilot Valve

⑧ Needle Type Regulating Valve

⑨ Needle Type Regulating Valve

⑩ Limit Switch

⑪ Electromagnetic Control Switch

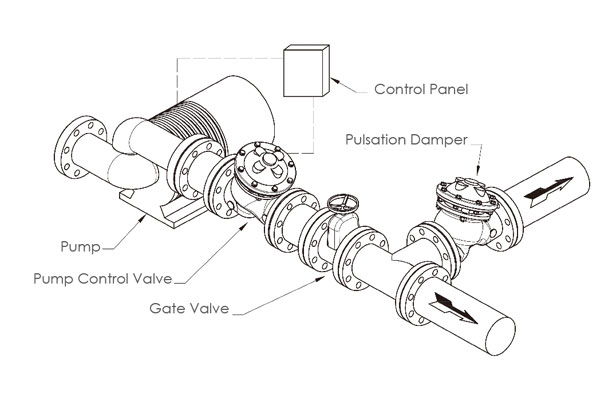

The installation of PF500 pump control valve is as shown in the diagram. The control circuits of the electromagnetic control switch and the limit switch must be sealed with flexible conduits.

Copyright © TALOAR All Rights Reserved