PN25/350PSI/Class 250

Globe Style Center-Oriented, Spring Actuated

Flange Dimension EN1092-2, ANSI B16.1

CF975-V

PN25/350PSI/Class 250

Globe Style Center-Oriented, Spring Actuated

Flange Dimension EN1092-2, ANSI B16.1

| Hydraulic Pressure Test | |

| Body | 3.75Mpa/37.5Bar |

| Seat | 2.75Mpa/27.5Bar |

| Sealing Performance | |

| EPDM | -20℃- 120℃ |

| NBR | -10℃- 80℃ |

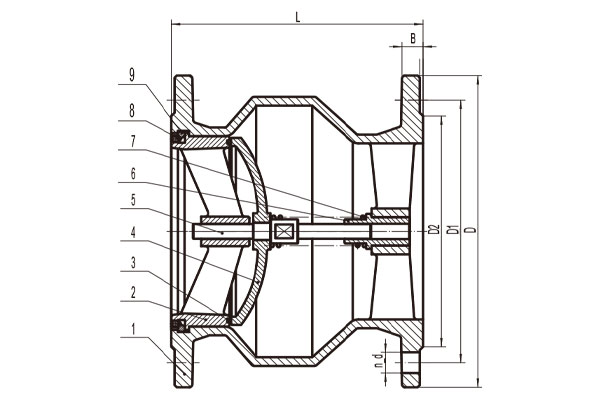

| No | Part | Specification | BS EN | ASTM |

| 1 | Body | Ductile Iron | BSEN1563 | A536 65-45-12 |

| 2 | Seat Body | Ductile Iron | BSEN1563 | A536 65-45-12 |

| 3 | Seat | Rubber | EPDM | EPDM |

| 4 | Disc | Ductile Iron/Stainless Steel | BSEN1563 | A536 65-45-12 |

| 5 | Stem | Stainless Steel | BS970 304S15 | S30400 |

| 6 | Bushing | Brass | BS2874 | B16 C36000 |

| 7 | Spring | Stainless Steel | BS970 304S15 | S30400 |

| 8 | Screw | Stainless Steel | BS970 304S15 | S30400 |

| 9 | Ball | Stainless Steel | BS970 304S15 | S30400 |

Applicable to water supply system pipelines

Stainless steel shell, valve core & stem assembly (Fig. CF370V)

| mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | |

| In | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | |

| L | 133 | 140 | 152 | 185 | 216 | 230 | 259 | 362 | 393 | 400 | 448 | |

| D | 165 | 185 | 200 | 235 | 270 | 300 | 360 | 425 | 485 | 555 | 620 | |

| D1 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | |

| D2 | 99 | 118 | 132 | 156 | 184 | 211 | 274 | 330 | 389 | 448 | 503 | |

| B | 19 | 19 | 19 | 19 | 19 | 20 | 22 | 24.5 | 27.5 | 30 | 32 | |

| n-d | 4-19 | 8-19 | 8-19 | 8-23 | 8-28 | 8-28 | 12-28 | 12-31 | 16-31 | 16-34 | 16-37 | |

| Weight | Lbs | 17 | 21 | 22 | 34 | 44 | 62 | 102 | 178 | 246 | -- | -- |

| Kg | 8 | 9 | 10 | 15 | 20 | 28 | 46 | 81 | 112 | -- | -- | |

Silent check valves should be installed at the outlets of pumps.

Valves may be installed in any positions of horizontal or vertical pipelines, Not applicable to air compression pipelines.

Copyright © TALOAR All Rights Reserved