Precise pressure control

Small volume and light weight

Fast opening, to guarantee pipeline pressure

Non-slam design, to prevent fluid impact

Built-in strainer, to prevent the guide piping system from being blocked

Precise pressure control

Small volume and light weight

Fast opening, to guarantee pipeline pressure

Non-slam design, to prevent fluid impact

Built-in strainer, to prevent the guide piping system from being blocked

Body/Bonnet: Ductile Iron/Stainless Steel

Disc & Stem: Stainless Steel

Piping: Bronze/Stainless Steel/Rubber Hose

Diaphragm: EPDM

Fasteners and Springs: Stainless Steel

175PSI/235PSI

10Bar/16Bar

ANSI / BSEN / ISO / DIN

0°C~100°C normal temperature water

Pressure Regulating Range: 0.1~5 kgf/cm², 2~9 kgf/cm², 7~17 kgf/cm²

Pressure Regulator Material: Bronze/Stainless Steel

Valve figure number/size/pressure grade/connecting end type/pressure regulating range/other optional accessories

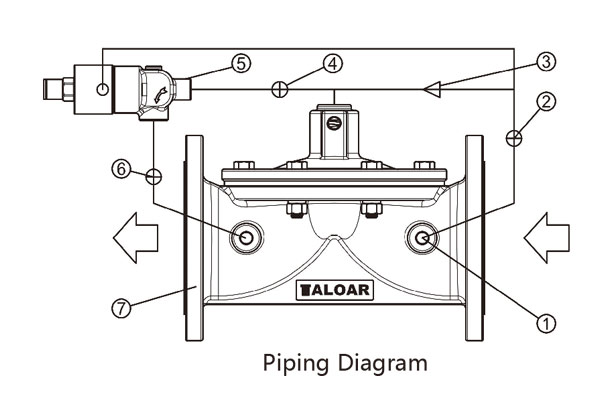

Note: In valve installation, it is strongly suggested that sufficient space should be left for easy maintenance in the future. A strainer shall be mounted in front of the valve to prevent foreign matters from blocking the valve.

① Strainer

② Ball Valve

③ Needle Type Regulating Valve

④ Ball Valve

⑤ Pressure Relief Valve

⑥ Ball Valve

⑦ Body

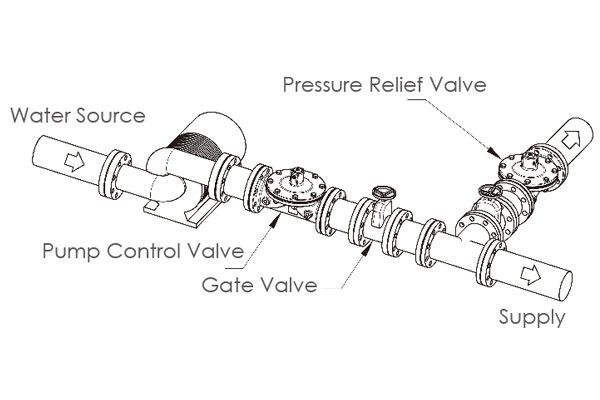

To prevent high-pressure impact generated during pump shutdown, the quick opening and slow closing the pressure relief valve can be used to release excess high pressure to protect the system.

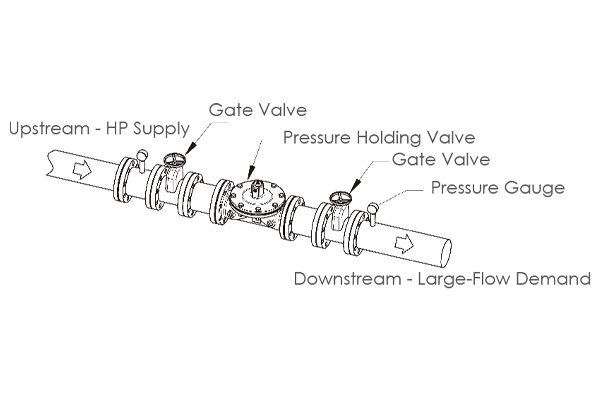

When the valve is installed between the high-pressure supply at upstream and large-flow demand at downstream, a pressure holding valve is used to maintain high pressure at upstream, so as to prevent pressure in the main pipe from dropping continuously due to excessive flow demand at downstream to maintain pressure in the main pipe.

Copyright © TALOAR All Rights Reserved