Sensitive and precise pressure control

Small volume and light weight

Easy regulating and maintenance

Excellent sealing performance

Built-in strainer, to prevent the guide piping system from being blocked

Sensitive and precise pressure control

Small volume and light weight

Easy regulating and maintenance

Excellent sealing performance

Built-in strainer, to prevent the guide piping system from being blocked

PR300 lightweight pressure reducing valve can automatically reduce high pressure at the inlet to a stable low pressure at outlet regardless of changes in fluid velocity or inlet pressure. Maintain outlet pressure within the preset range by a precise pressure regulator. When outlet pressure exceeds the set range of the pressure reducing valve, the basic valve body and the pressure regulator will automatically close to form a tight seal.

If the optional check feature is selected, when the back pressure is generated, the return fluid will enter the air chamber to close the valve to prevent the fluid from back flow.

Body/Bonnet: Ductile Iron/Stainless Steel

Disc & Stem: Stainless Steel

Piping: Bronze/Stainless Steel/Rubber Hose

Diaphragm: EPDM

Fasteners and Springs: Stainless Steel

175PSI/235PSI

10Bar/16Bar

ANSI / BSEN / ISO / DIN

0°C~100°C normal temperature water

Pressure Regulating Range: 0.1~5 kgf/cm², 5~9 kgf/cm², 7~17 kgf/cm²

Pressure Regulator Material: Bronze/Stainless Steel

Valve figure number/size/pressure grade/connecting end type/pressure regulating range/other optional accessories

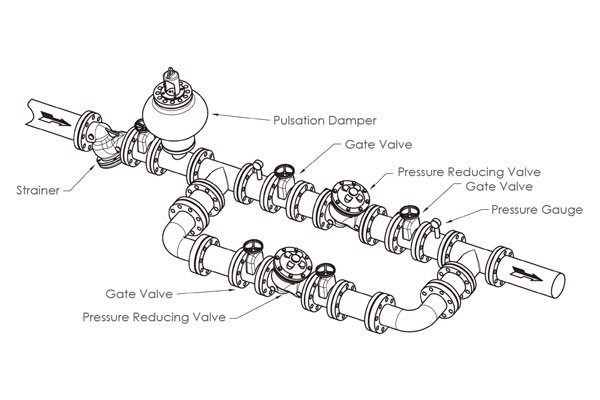

Note: In valve installation, it is strongly suggested that sufficient space should be left for easy maintenance in the future. A strainer shall be mounted in front of the valve to prevent foreign matters from blocking the valve.

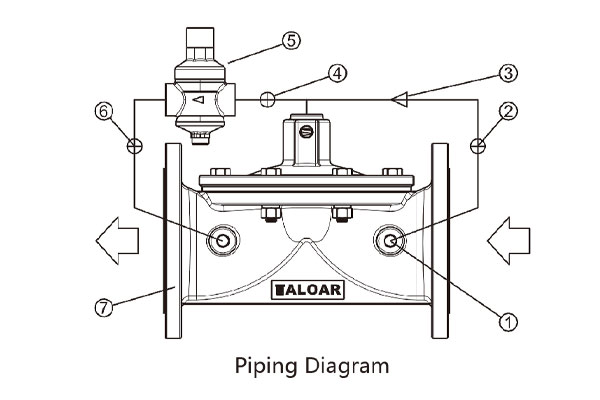

① Strainer (Built-In)

② Ball Valve

③ Needle Type Regulating Valve

④ Ball Valve

⑤ Pressure Reducing Valve

⑥ Ball Valve

⑦ Body

If the flow demand varies in a large range, multiple PR300 pressure reducing valves should be used in parallel. In case of large flow demand, two pressure reducing valves should work simultaneously. In case of small flow demand, the large-size valve will automatically close, while the small-size valve will continue to provide the required flow. When setting the pressure regulating range for the valves, the set pressure of the small-size valve should be about 0.3 kgf/cm² higher than that of the large-size valve.

If the pressure reduction range is large, multiple PR300 pressure reducing valves should be used in series for sectional pressure reduction.

Copyright © TALOAR All Rights Reserved