Smooth action, without impact

Easy regulating and maintenance

Excellent and reliable sealing performance

Controllable opening and closing speed

Built-in strainer, to prevent the piping system from blocking

Smooth action, without impact

Easy regulating and maintenance

Excellent and reliable sealing performance

Controllable opening and closing speed

Built-in strainer, to prevent the piping system from blocking

The valve is particularly suitable for use in the occasions where absolute sealing is required. Its rubber seal ring can ensure that the valve is free from leakage. In addition, the simple design of the valve can also ensure reliability.

Body/Bonnet: Ductile Iron/Stainless Steel

Disc & Stem: Stainless Steel

Piping: Bronze/Stainless Steel/Rubber Hose

Diaphragm: NBR

Fasteners and Springs: Stainless Steel

175PSI/235PSI/350PSI

10Bar/16Bar/25Bar

ANSI / BSEN / ISO / DIN

0°C~100°C normal temperature water

Valve figure number/size/pressure grade/connecting end type/other optional accessories

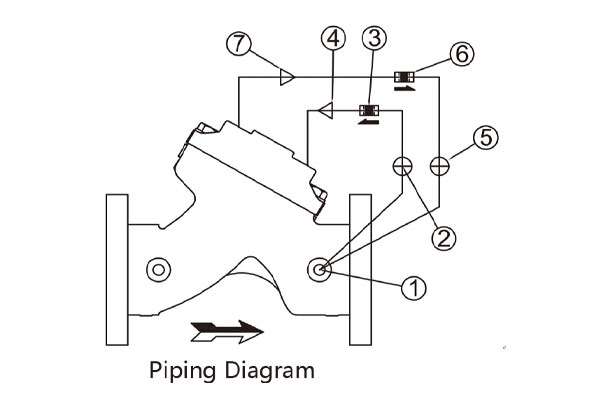

Note: In valve installation, it is strongly suggested that sufficient space should be left for easy maintenance in the future. A strainer shall be mounted in front of the valve to prevent foreign matters from blocking the valve.

① Strainer

② Ball Valve

③ Check Valve (Optional)

④ Needle Type Regulating Valve

⑤ Ball Valve

⑥ Check Valve (Optional)

⑦ Needle Type Regulating Valve

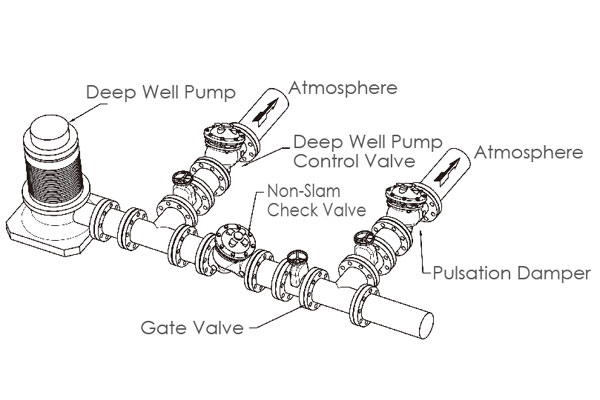

In occasions where a deep well pump is required in design, the non-slam check valve should be installed. When the pump is shut down or sudden powered off, the non-slam check valve will close slowly to avoid the damaging water hammer caused by rapid back flow of fluid.

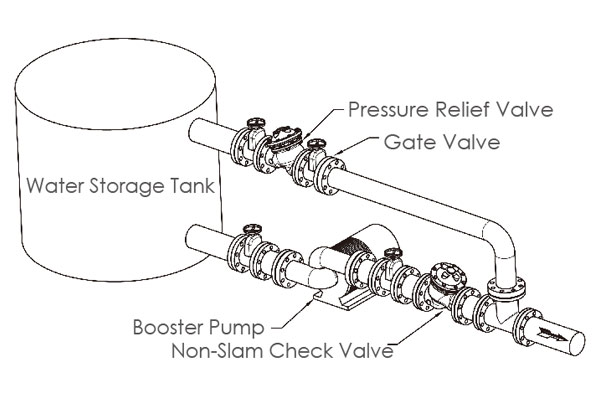

Install NC500 non-slam check valve at the outlet of booster pump can prevent fluid from entering the water storage tank when the pump is shut down. The pressure relief valve shown in the diagram can effectively prevent the impact occurring during pump shutdown.

Copyright © TALOAR All Rights Reserved