Unique diaphragm design

Unique check valve structure design

Lug type protective cover

Integrated body

Air chamber of various volumes available

Compact, light weight

Unique diaphragm design

Unique check valve structure design

Lug type protective cover

Integrated body

Air chamber of various volumes available

Compact, light weight

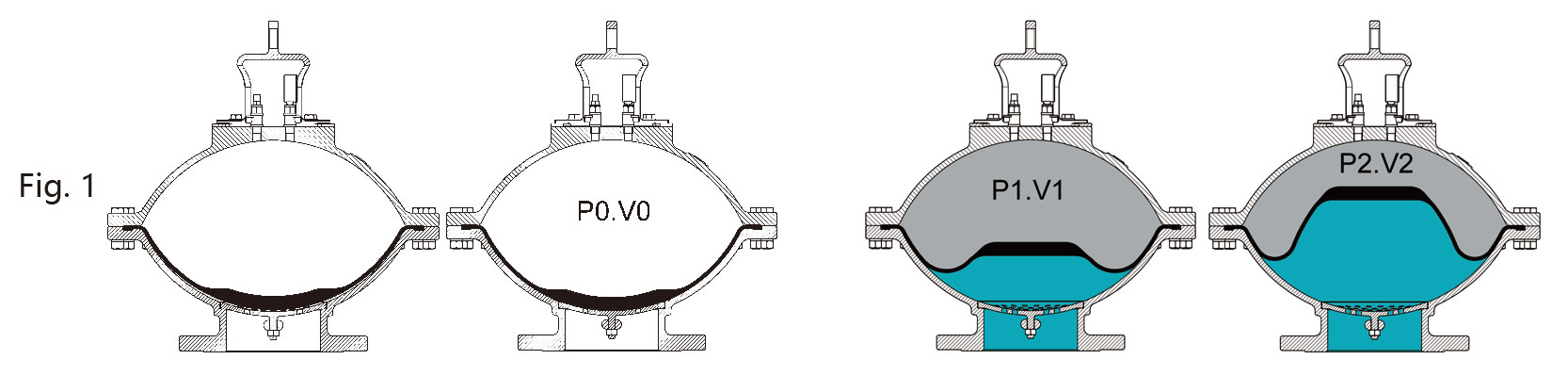

If the liquid pressure increases to P2, the gas volume will decrease to V2, and pressure will increase to balance liquid pressure. That is, the air chamber inside the pulsation damper is compressed, with the volume change △V=V1-V2. That way, the energy stored in the pulsation damper can be used.

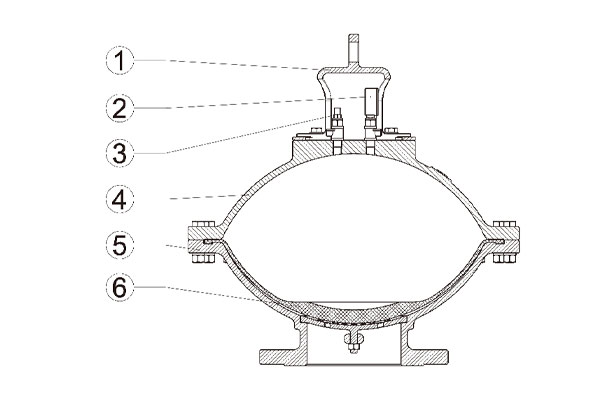

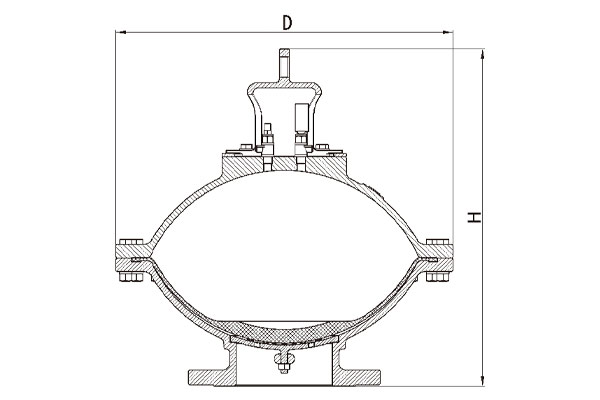

① Protective Cover (Ductile Iron)

② Pressure Gauge

③ Inflatable Nozzle (Stainless Steel)

④ Top Cover (Carbon Steel/Stainless Steel)

⑤ Shell (Stainless Steel)

⑥ Air Chamber (EPDM/VITON)

Max. Working Pressure: 25 bar;

Max. Allowed Pressure: 55 bar

0.7L, 3L, 6L,17L, 30L, 50L

ANSI / BSEN / ISO / DIN

Note: Water hammer eliminators with different chamber capacities can be calculated based on the actual pipe length, flow rate, head and other parameters provided by the user on site for special use environments.

Note: Water hammer eliminators with different chamber capacities can be calculated based on the actual pipe length, flow rate, head and other parameters provided by the user on site for special use environments.

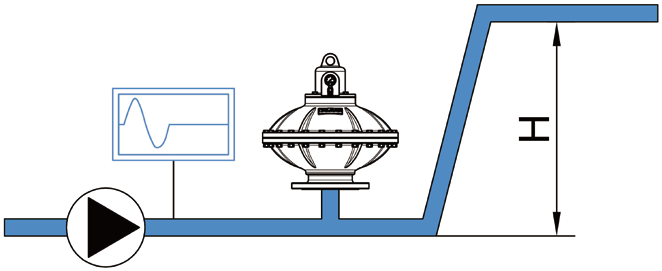

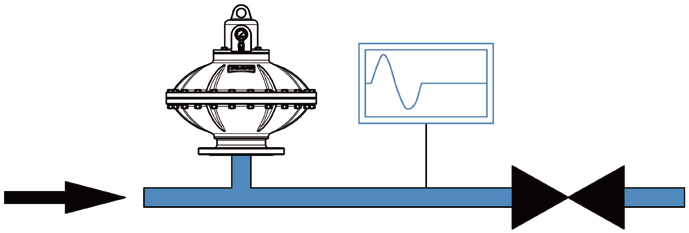

If there is a sudden power off for the pump while transporting the liquid to a high spot, the liquid in the pipeline will return and accelerate in the pipeline. Water hammer with great destructive power will be formed at the check valve that is installed at the outlet of the pump. If the pipeline is long, the water hammer may cause the pipeline to bust. The longer the pipeline, the longer the fluid accelerate, the bigger the impact. TALOAR pulsation damper can effectively absorb such water hammer. Besides, TALOAR pulsation damper is designed with a unique check valve structure with "fast-in and slow-out" feature, can effectively absorb water hammer instantly. It takes relatively long time to release excess pressure, ensuring stable pressure in the pipeline system.

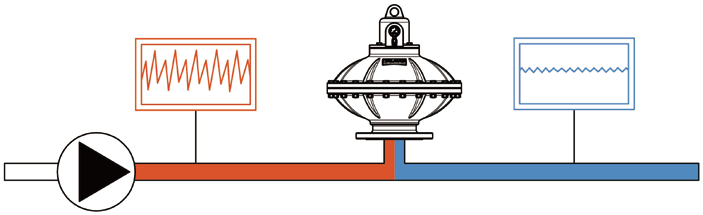

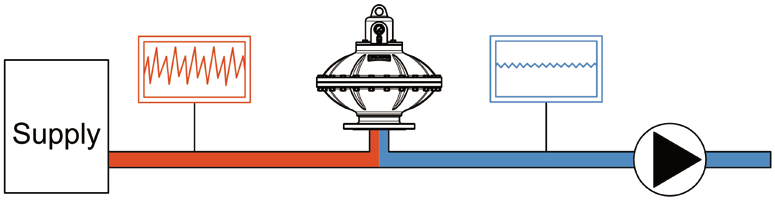

The cyclic piston movement within the circulating pump will naturally generate water hammer and hydraulic impacts. During the discharge stroke of the pump, excess liquid will enter the pulsation damper to absorb excess pressure. During the piston return, the liquid absorbed in the pulsation damper will enter the system to supplement the pressure drop caused by the piston return of the pump to finally stabilize system pressure.

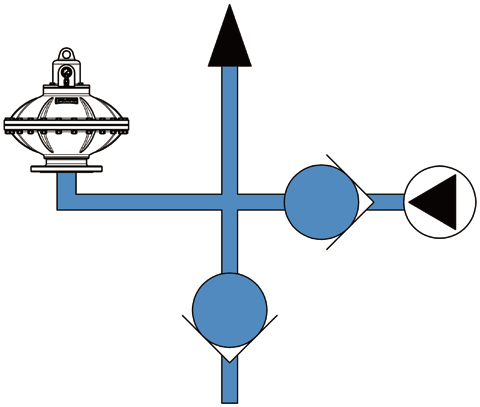

If there is no sufficient water supply, the pump efficiency will highly affected. Pitting is related to the fluid velocity, acceleration, and friction. If the supply at pump suction is insufficient, vacuum will form at the supply under the suction of the pump, resulting in "pitting".

Install TALOAR pulsation damper at the pump suction. This will act a buffer pool: If the suction of the pump is insufficient, the liquid stored in the pulsation damper will be supplied to the system to ensure the pump suction is sufficient. If the system supply is too large, excess liquid will enter the pulsation damper to ensure pump suction is stable, thus greatly improving the service life of the pump.

All liquid flow has kinetic energy. When the fluid suddenly stopped, its kinetic energy will convert into pressure and this very dangerous. Such "water hammer phenomenon" usually occurs in pipeline systems with quick-closing valves. The destructive power generated by "water hammer phenomenon" is strong enough to damage devices like pipelines, valves, and pumps.

There are many reasons for "water hammer phenomenon", such as quick-closing valves, back pressure impact, pump start-up or shutdown and sudden loss of power in the system (such as power failure).

If the system experiences sudden power off or pump failure, TALOAR pulsation damper can maintain pressure within the system for a short time to ensure that other moving and working parts are still lubricated and cooled, so as to protect the equipment.

When liquid flows in a closed system, the liquid temperature will rise due to friction or other reasons, the resulting liquid expansion will cause the system pressure to increase. If the pressure exceeds safety pressure limit of the system, it will cause the pipeline to bust, valve failure, damage to precision instruments on the pipelines. Besides, in case of system leakage, the liquid in the pipelines may cause permanent damage to personnel and the surrounding environment. Use TALOAR pulsation damper will absorb the excess pressure caused by the thermal expansion of the liquid to ensure the safe operation of the system.

If the pressure parameters of the system are extremely important for safety operation of the system, the instruments measuring such parameters are not allowed to contact with the fluid in the system, Now TALOAR pulsation damper can help solve this problem. In this case, the diaphragm of TALOAR pulsation damper performs an isolation function.

| Size(mm) | Size(in) | H(mm) | D(mm) | Volume(ml) |

| 50 | 2 | 240 | 180 | 700 |

| 65 | 21/2 | 355 | 300 | 3000 |

| 80 | 3 | 355 | 300 | 3000 |

| 100 | 4 | 395 | 360 | 6000 |

| 125 | 5 | 395 | 360 | 6000 |

| 150 | 6 | 500 | 500 | 17000 |

| 200 | 8 | 565 | 570 | 30000 |

| 250 | 10 | 565 | 570 | 30000 |

| 300 | 12 | 620 | 650 | 50000 |

Note:

The absorption effect of the pulsation damper on water hammer is not based on diameter, but on the volume, because the volume of the pulsation damper with the same diameter can vary greatly. For example, for a 4" pulsation damper, its volume is 10 L or 100 L. When it is applied in the same system, the pulsation damper with the volume of 100 L has better absorption effect on water hammer.

TALOAR 2" pulsation damper can hold the volume of 10 L or 100 L. If wrong pulsation damper is selected, the same 2" pulsation damper can perform not even 1/4 absorbing effect in compare with 2” pulsation damper with the corrected volume.

| Polymer | ISO | Applicable TEMP(℃) | Applicable Media |

| Standard Nitrile Butadiene Rubber |

NBR | -20+85 | Mineral oil, vegetable oil, silicone oil, lubricating oil, water for industrial use, ethylene glycol, nonflammable liquid (HFA-HFB-HFC), aliphatic, carbon hydride, butane, diesel oil, fuel oil, etc. |

| Low-TempResistant NitrileButadieneRubber |

NBR | -40+70 | Those media applicable to standard nitrile butadiene rubber, and various Freons (the content of acrylonitrile in low-temperature resistant nitrile butadiene rubber is less than that in standard nitrile butadiene rubber, so the low-temperature resistant nitrile butadiene rubber is more suitable for use in low-temperature environment, but its chemical resistance is poor) |

| Nitrile For Hydride | NBR | -10+90 | Regular premium aromatic gasoline (and those media applicable to standard nitrile butadiene rubber) |

| Hydrogenated Nitrile | HNBR | -50+130 | Those media applicable to standard nitrile butadiene rubber (but with better effect in both high-temperature and low-temperature environments) |

| Used In The Food Industry | NBR | -20+85 | Food (specify when ordering) |

| Butyl | IIR | -20+90 | Phosphate ester, hot water, ammonia, some Freons (22-31-502), alkaline soda, ethylene glycol brake oil, some acid alcohol,ketone, ester, skyrol7000, etc. |

| Ethylene Propylene | EPDM | -20+90 | Brake oil, hot water, leachate, detergent, alkaline water (HFC), many acids and alkalis, saline alkali solution, skydrol500, etc |

| Chloroprene | CR | -20+85 | Freons (12-21-22-113-114-115), aqueous solution, ammonia, carbon dioxide, mineral oil, paraffin oil, silicone oil |

| Epichlorohydrin | ECO | -30+100 | Leaded gasoline, mineral oil |

Copyright © TALOAR All Rights Reserved