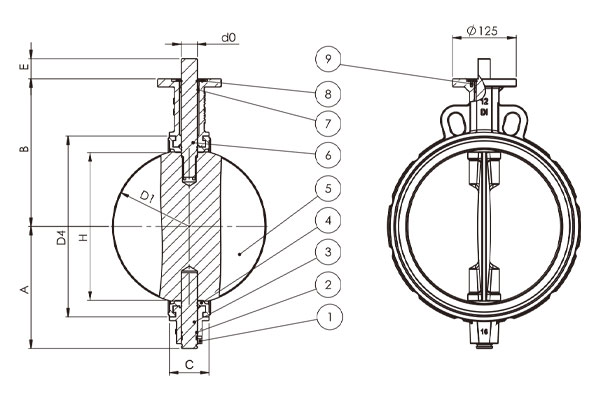

PN16/235PSI/Class125

Wafer Style, Pin-Free Valve Shaft, Seal-Line Seat

Design to BS5155 and MSS SP-67

Flange Dimension to EN1092-2, ANSI B16.1 Class 125

HB950-L/G/O

PN16/235PSI/Class125

Wafer Style, Pin-Free Valve Shaft, Seal-Line Seat

Design to BS5155 and MSS SP-67

Flange Dimension to EN1092-2, ANSI B16.1 Class 125

| Sealing Performance | |

| EPDM | -20℃-120℃ |

| NBR | -10℃-80℃ |

| VITON | -20℃-150℃ |

| Hydraulic Pressure Test | |

| Body | 2.4Mpa/24Bar |

| Seat | 1.76Mpa/17.6Bar |

| No | Part | Specification | BSEN | ASTM |

| 1 | Body | DuctileIron | BSEN 1563 | A536 65-45-12 |

| 2 | Bottom Stem | Stainless Steel | BSEN10088-1 | A582 420 |

| 3 | O-Ring | NBR | NBR | NBR |

| 4 | Seat | EPDM NBR VITON |

EPDM NBR VITON |

EPDM NBR VITON |

| 5 | Disc | Ductile Iron Stainless Steel Aluminum Bronze |

BSEN 1563 BS970 304S15 1400AB2 |

A536 65-45-12 CF8 B148 Ay 954 |

| 6 | Upper Stem | Stainless Steel | BSEN 10088-1 | A582 420 |

| 7 | Nameplate | Aluminum | PTFE&Bronze | PTFE&Bronze |

| 8 | Screw | Steel | BSEN 10087 | A307 |

| 9 | Retaining Cap | Steel | BSEN 10087 | A307 |

Suffix - L for operation by lever, - G for operation by worm gear, - O for polished rod

An electric or pneumatic actuator may be mounted to match an ISO5211-based mount.

Please refer to the TALOAR Butterfly Valve Torque Table in Page 46.

| mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| In | 2 | 2½ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | |

| A | 78 | 90 | 99 | 120 | 134 | 142 | 178 | 203 | 240 | |

| B | 120 | 137 | 145 | 160 | 175 | 189 | 220 | 250 | 290 | |

| C | 43 | 46 | 46 | 52 | 56 | 56 | 62 | 68 | 78 | |

| E | 30 | 30 | 30 | 30 | 30 | 30 | 40 | 40 | 40 | |

| H | 23.9 | 39.5 | 60.3 | 87.3 | 106.5 | 142.3 | 193.2 | 242.2 | 290.2 | |

| D4 | 83 | 95.5 | 138.0 | 139.0 | 167.0 | 194.0 | 247.6 | 300.0 | 352.0 | |

| d0 | 12.60 | 12.60 | 12.60 | 15.77 | 18.92 | 18.92 | 22.10 | 28.45 | 31.60 | |

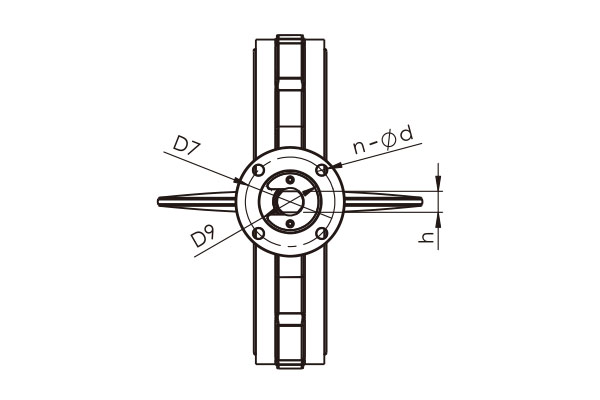

| h | 9 | 9 | 9 | 11 | 14 | 14 | 17 | 22 | 24 | |

| D6 | 90 | 90 | 90 | 90 | 90 | 90 | 125 | 125 | 125 | |

| D7 | 70 | 70 | 70 | 70 | 70 | 70 | 102 | 102 | 102 | |

| D9 | 55 | 55 | 55 | 55 | 55 | 55 | 70 | 70 | 70 | |

| n-Φd | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-10 | 4-12 | 4-12 | 4-12 | |

| ISO5211 | F07 | F07 | F07 | F07 | F07 | F07 | F10 | F10 | F10 | |

| Weight | Lbs | 7.7 | 8.8 | 10.1 | 12.6 | 16.3 | 22.3 | 40.1 | 52.5 | 81.6 |

| Kg | 3.5 | 4.0 | 4.6 | 5.7 | 7.4 | 10.1 | 18.2 | 23.8 | 37.0 | |

Copyright © TALOAR All Rights Reserved